Product Introduction

Thank you for choosing the desktop ultraviolet ozone cleaning machine GXT10A-01 produced by Beijing Aerospace Hongda Optoelectronic Technology Co., Ltd. This product has good cleaning effect, easy operation, safety and reliability, and simple maintenance. The GXT10A-01 cleaning machine has a small size, high cleaning power, and is equipped with an air cooling circulation system, successfully solving the common heat dissipation problem in cleaning machines.

technical parameter

working principle

Ultraviolet light is an invisible light with a wavelength range of 1360 × 10-10m~3900 × 10-10m. According to the wavelength range, it can be divided into three bands: A, B, C, and vacuum ultraviolet: ① A band 320nm~400nm; ② B-band 275-320nm; ③ C-band 200nm~275nm; ④ V-band - vacuum ultraviolet light 100-200nm. The effects of ultraviolet light in various wavelength ranges are different, some are used for sterilization, some for cleaning, some for photolithography, and some for curing. UV lamps can be divided into instant start type, cold cathode type, and hot cathode type according to their starting and working modes. For situations with the same power consumption, instant start type has the strongest irradiation power. In addition, the irradiation power of the lamp also varies with the temperature of the surrounding area and the pipe wall, so it is necessary to control the temperature of the surrounding area and the pipe wall of the ultraviolet lamp well in order to achieve the best effect of the ultraviolet lamp.

In the manufacturing process of LCD displays, the cleanliness requirements for ITO glass are very high. To produce products with a line spacing and line width of 10 μ m and ensure a high yield rate, the coating requirements before exposure are quite high. To improve the coating effect, the first step is to ensure that the glass is clean. In previous cleaning techniques (chemical cleaning and physical cleaning), it was often difficult to achieve this cleanliness requirement. How to improve the cleanliness of glass surfaces and enhance the effectiveness of film application? At present, UV ultraviolet cleaning is widely used abroad, which can avoid pollution caused by the use of organic solvents and shorten the cleaning process. Its working principle is to use the photosensitive oxidation effect of ultraviolet photons on organic substances to achieve the purpose of cleaning organic compounds (hydrocarbons) adhered to the surface of objects. In practical applications, a UV lamp that can generate two wavelengths is usually used. This UV lamp can produce ultraviolet light with wavelengths of 254nm and 185nm (usually only 20% of the 254nm wavelength is 185nm). The working process is that most organic compounds have strong absorption ability for ultraviolet light with a wavelength of 254nm. After absorbing ultraviolet light, they decompose into ions, free atoms, excited molecules, and neutral molecules, which is called photosensitivity. After absorbing ultraviolet photons with a wavelength of 185nm, oxygen in the atmosphere produces ozone O3 and atomic oxygen O. The generated O3 has a strong absorption effect on ultraviolet light with a wavelength of 254nm. Under the action of photons, ozone decomposes into oxygen and atomic oxygen O. Due to the extremely active nature of atomic oxygen, the photosensitive decomposition products of carbon and hydrogen compounds on the surface of objects are oxidized to form volatile gases such as carbon dioxide, nitrogen, and water vapor, which escape from the surface of objects, thus achieving the goal of completely removing stubborn organic substances adhered to the surface of objects. The cleaning principle is shown in the following figure:

Here, a reflective plate is used in conjunction to reflect the UV light emitted by the UV lamp onto the glass substrate, thereby enhancing the intensity of light exposure on the glass substrate. In terms of device implementation, there are three important factors that must be paid attention to and controlled, which are: first, to maintain a small distance between the glass substrate and the UV lamp, usually less than 10mm, in order to provide sufficient light intensity and avoid blind spots. 2、 To maintain an appropriate concentration of O3 in the chamber of the cleaning machine, too much or too little is not conducive to achieving the final cleaning effect. Usually, the O3 concentration is controlled within the range of 100-130ppm. 3、 The temperature of the furnace chamber cannot be too high, so it is necessary to pay attention to cooling and control the working temperature of the furnace chamber to prevent deformation of the ultraviolet lamp due to overheating or loss of ultraviolet irradiation power.

Related experiments have shown that after chemical and physical cleaning, the contact angle of the glass surface (the main parameter for measuring the cleanliness of an object's surface, which is the angle formed by a quantitative drop of pure water on the object's surface) can only be around 50 degrees, which is far from enough for STN products. After UV cleaning, the contact angle can be reduced to below 20 degrees, which can meet the process requirements of STN products.

UV ozone light cleaning machine GXT10A-01

Installation instructions

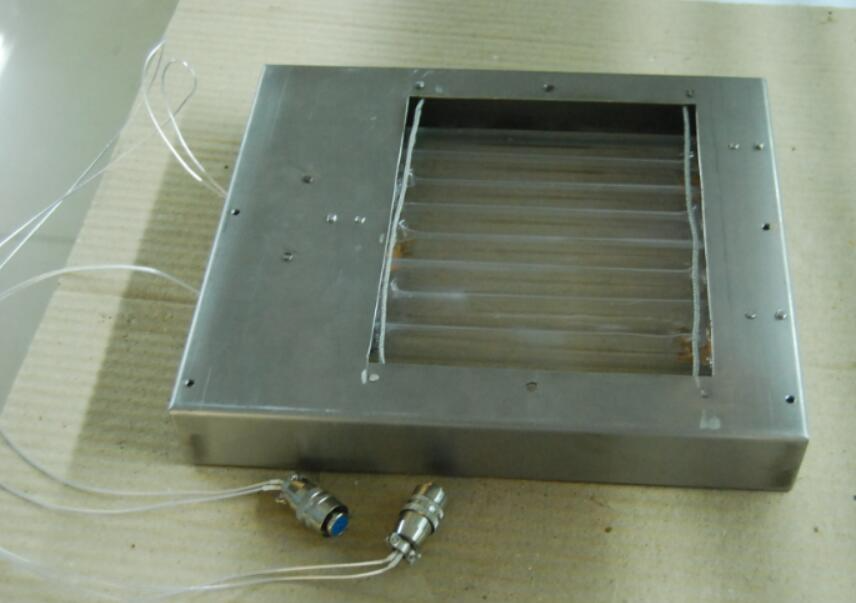

Introduction: Please check the completeness of the components before assembly, as shown in the packing list. The system is not equipped with inlet and outlet ducts before leaving the factory. Please purchase corresponding axial flow fans, inlet ducts, and exhaust ducts according to the size requirements.

1、 Install air cooling system

1. Fixed installation of axial flow fan.

2. Connect the ventilation ducts according to the requirements of the environment.

3. After installation, debug.

二.组装清洗机

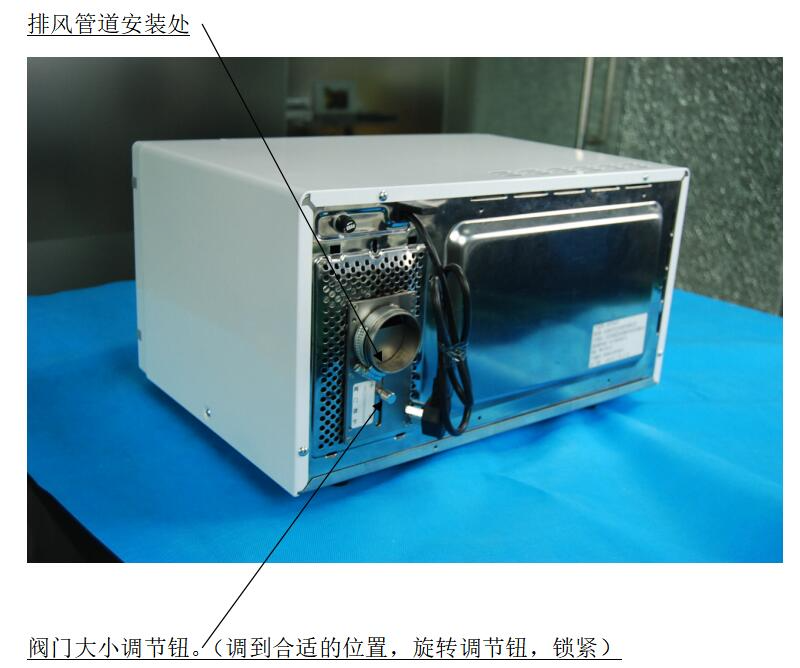

安装紫外线灯组件 将清洗机的废气出口用排风管道连接到净化间的排风管道。注意:清洗机的排风包含高温(<80℃)臭氧和清洗废气,请保证排风管道的连接通畅,密闭严谨. (示意图)

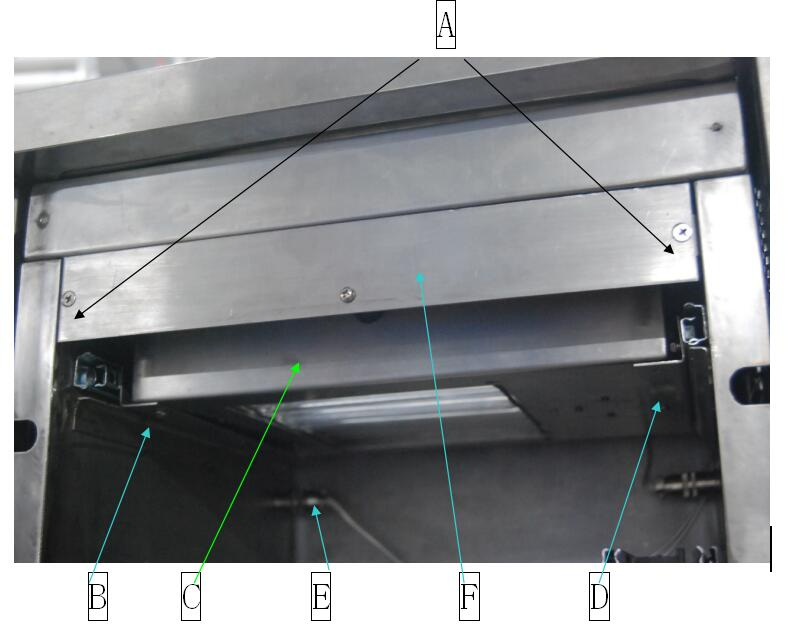

Steps for replacing UV lamp components:

1. Use a Phillips screwdriver to unscrew the two screws at point A

2. Remove the baffle F

3. Pull out the ultraviolet lamp component C

4. Use a Phillips screwdriver to unscrew screws B and D

5. Unplug the cable plug E

6. Remove the UV lamp component

7. Reverse the order of taking the ultraviolet lamp components from bottom to top, which is the step of installing the ultraviolet lamp components

technical parameter

Equipment parameters

Equipment model: GXT10A-01

Dimensions (mm): 511 × 399 × 284.5

Maximum size of cleaned workpiece (mm): 120 × 120

Stage swing: ± 7.5mm

Work environment requirements: 0-40 ℃

Ozone leakage:<0.16ppm

Surface temperature of processed material: < 55 ℃

Working voltage: AC 220V 50Hz

Maximum working power during operation: 150W

Standby power during operation: 120W

Component parameters: Lamp power: 120W (120W × 1)

Lamp shape: Serpentine shaped

Lamp type: using dual band ultraviolet light source

Lamp lifespan:>5000 hours (illumination>70%)

Illumination distance: 1~85mm Adjustable illuminance: 1-45mw/cm2 Function introduction Plug in power supply

After the UV ozone light cleaning machine is powered on, the buzzer will sound and the program will enter the demonstration mode. Press the 'Cancel' button to return to standby mode.

(1) Press the "Start" button, and the UV ozone light cleaning machine will start working;

(2) Press the "Start/+30 seconds" button during operation to increase the cleaning time by 30 seconds

The maximum cleaning time is 99 minutes and 90 seconds;

When the cleaning time reaches the set time, the buzzer will sound twice to remind that the cleaning is complete.

matters needing attention

1. Ensure reliable grounding of the entire machine

2. The maximum power consumption of the whole machine is 150W. Please ensure that sufficient distribution power can be provided.

Maintenance and upkeep

1. Regularly disassemble and clean the machine.

2. The whole machine must replace the lamp after working for about 3000 hours

Method for replacing the lamp tube:

After working for more than 3000 hours, the exposure of the ultraviolet lamp will decrease below the national standard. At this time, the lamp tube can be treated as scrap and must be replaced. Frequent long-term startup can also reduce the lifespan of ultraviolet lamps.

be careful:

When replacing the lamp, please do so in a clean environment.

2. Pay attention to ensuring that the surface of the replaced lamp tube is clean.

3. This system often uses standard components. Please install all removed screws back to their original positions and do not leave them inside the machine.

Replace insurance:

In case of poor input current condition and misoperation, the fuse will automatically melt. Please replace the fuse

Troubleshooting

1. The whole machine does not work

Is the power supply reliably connected

Is the power supply sufficient

Is the fuse of the entire machine blown

2. The UV light is not on

Is the ballast working properly

Is the door of the cleaning compartment tightly closed

Check if the power supply of the entire machine meets the requirements

Tips

(1) In the function setting state, the digital display shows the corresponding settings;

(2) The effective button buzzer beeps once, while the invalid button does not respond;

(3) In both running and paused states, the digital display shows the remaining cleaning time;

(4) After unpacking, please remove the transparent adhesive tape located inside the UV ozone light cleaning machine and thoroughly clean it with cleaning solution before use to ensure cleaning effectiveness;

(5) There are metal hose samples in the packaging box, customers can purchase them from the market according to the metal hose samples and connect the air duct.