Zhang Runsong, founder of Aerospace Hongda, introduced:

Born in March 1940 in Qinhuangdao City, Hebei Province.

In 1964, graduated from the radio major of Beihang University and completed five years of undergraduate studies with excellent grades.

From 1964 to 1997, he was assigned to Room 6 of the 23rd Institute of the Second Academy of the Ministry of Space, engaged in technological innovation, research and development, and product design work for aerospace weapons products, lasting for 34 years.

In 1998, he started his own business and served as the general manager and technical leader.

Zhang Runsong has been engaged in research and development for over 50 years, from the Ministry of Aerospace to his retirement and entrepreneurship. He has been responsible for key elements and links in the industry chain such as research and development, application, and industrialization on the front line. Years of technical experience, from technician, engineering team leader (project leader), to technical director of the research laboratory, serving as an engineer, senior engineer, chief designer, and member of the Institute's Science and Technology Committee; From the design of basic circuits, subsystem design, to the overall design of large-scale systems, to the technical commander in charge of major projects; Since graduating as a technician, I have completed a large number of hardware (digital and analog circuits) designs, combination designs, whole machine designs, system designs, etc. for aerospace weapon systems for 36 years. In addition to hardware, a large amount of software design has also been completed. The project that won the second prize for scientific and technological progress from the Ministry of Space, as the first author, undertook a quarter of the hardware design and one person completed all the software design.

During my tenure at the Ministry of Aerospace, I have supervised many large-scale projects such as:

Anti missile system 101 radar command control system

HQ7 distance channel (signal processing system)

Weapon automation testing system, air to ground signal processing system

Received one National Science and Technology Conference Achievement Award and two Second Prize Ministerial Science and Technology Progress Awards respectively; And participated in the writing of the "Aerospace Series" (main author of the instruction control section).

During my tenure, I have received various awards and was recommended by my employer to be included in the "List of Chinese Engineer Celebrities". At the same time, he was also in charge of the "pulp automation control system" of several large-scale civilian projects such as Anshan paper mills, and the "water conservancy automation system scheme design for Anhui Pisihang irrigation area" (served as the leader of the joint group of the Ministry of Aerospace, Peking University, and Northern Jiaotong University). During his work in the Ministry of Aerospace, he received multiple awards and was first criticized as a senior engineer, known as a "technical genius".

After working at Aerospace Hongda, I was responsible for the design and system design of dozens of challenging projects, including the "Gallium Arsenide Single Crystal Horizontal Growth System" project, the "Vacuum UV Spectrometer project", and the "Special UV Light Source Production Line". Due to the experience of starting from the bottom level design, the professional knowledge learned is best applied, and the key technologies of each link from single machine to system, from core components to the whole machine are very clear. Therefore, the feasibility and reliability of the overall plan are relatively high, and almost all projects are successful. It is precisely because of a solid technical foundation that it is difficult to achieve principle transparency, clear technical routes, and ideal results; The product has stable performance, reliable quality, and low failure rate.

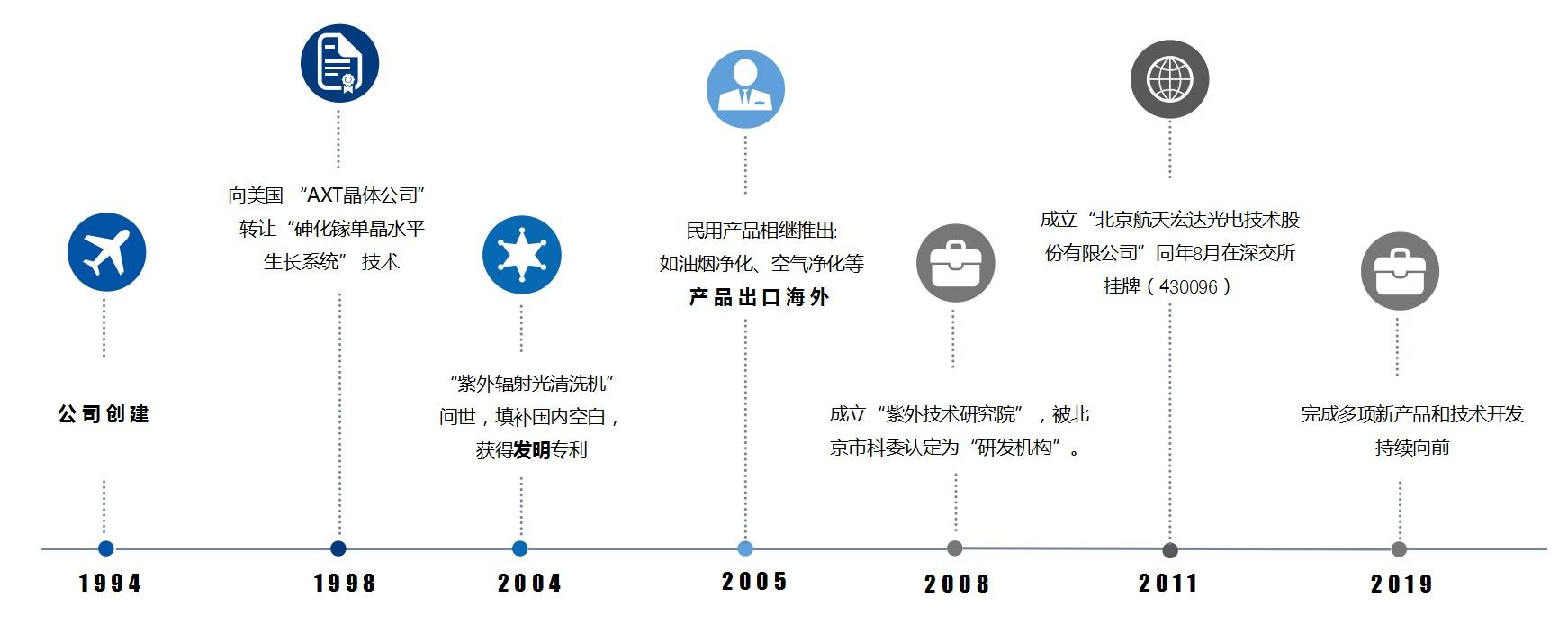

Research and Development History and Achievements

I have been serving as the head of the R&D department at Aerospace Hongda for over 20 years. The high technical content and difficulty of large-scale projects under the supervision are no less than military products; More challenging.

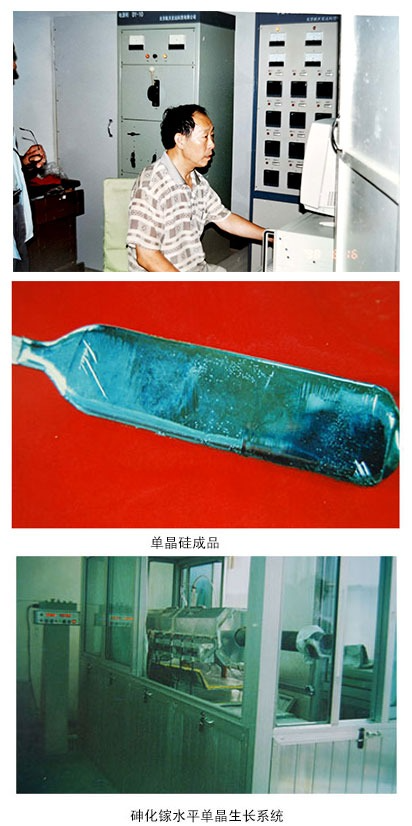

In 1998, led the team to complete the "Gallium Arsenide Single Crystal Horizontal Growth System" and successfully transferred the technology to AXT Crystal Company, a high-tech company listed in Silicon Valley, USA, earning the first bucket of gold for entrepreneurship;

In 2000, led the team to complete the development of the "motor controller" and exported it in small quantities to the United States, achieving the result of "3 years of use, 300 sets, and zero repair rate".

In 2001, the development of the "Logging Tilt Precision Gyroscope" was completed and successfully demonstrated in Zhongyuan Oilfield, achieving good results and filling the gap in China. Its accuracy and performance have reached the leading domestic and international levels, achieving "continuous testing" (which the United States has not achieved).

Since 2003, we have been dedicated to the research of ultraviolet technology.

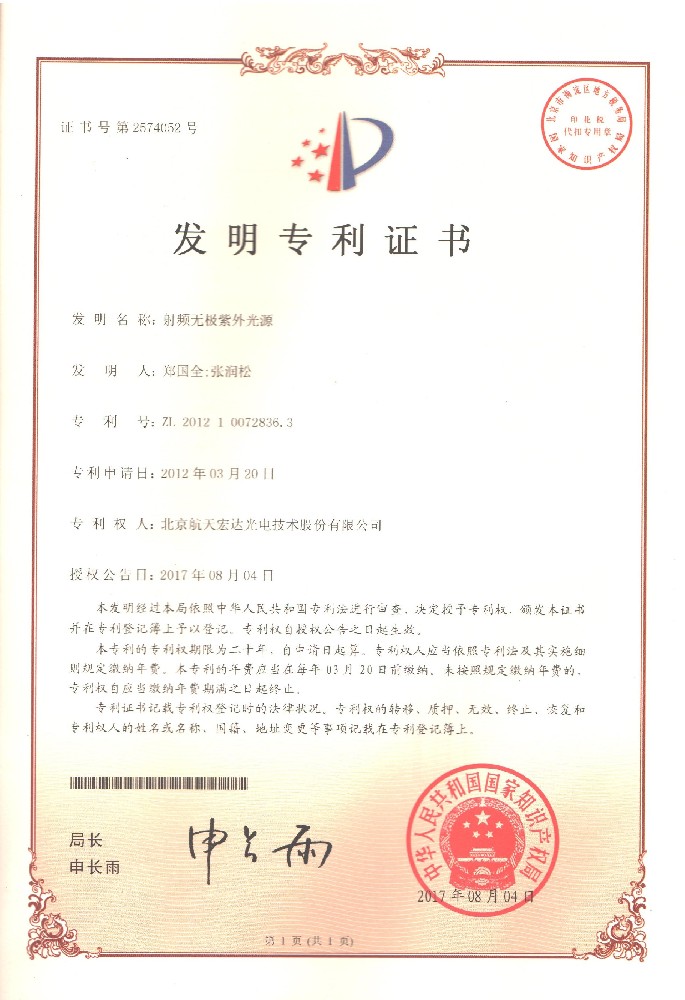

In 2004, I was in charge of and completed the design of the prototype of the "UV radiation cleaning machine". In 2006, I was granted an invention patent.

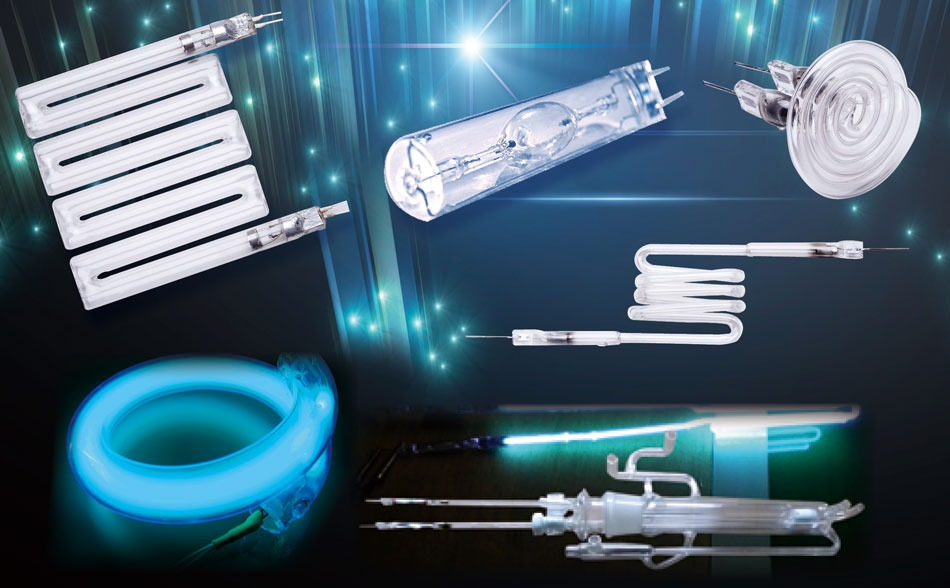

In 2005, I led the design and development of the first special ultraviolet light source experimental production line.

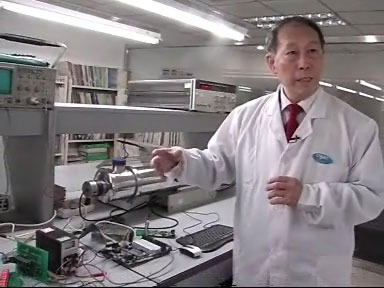

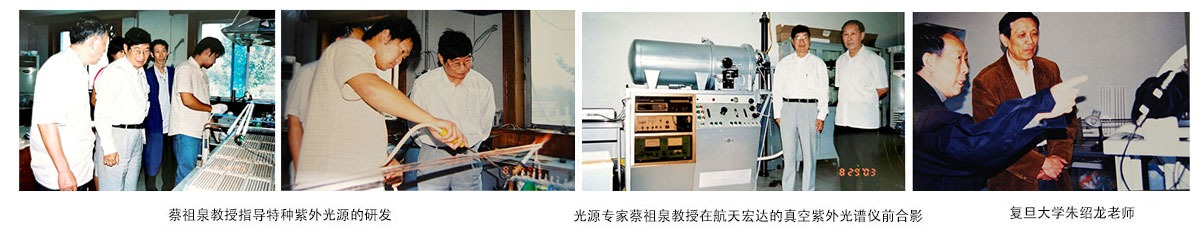

In 2006, I was in charge of and completed the overall design of the "Vacuum Ultraviolet Spectrometer", providing scientific support for the research of ultraviolet technology and filling the gap in China's detection instruments in the "vacuum ultraviolet band" of the "electric light source" field.

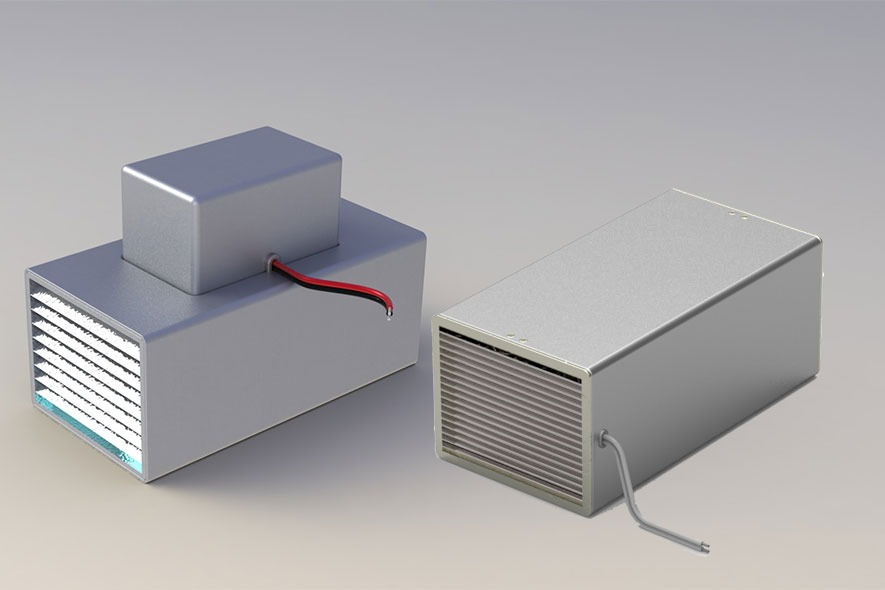

In 2006, the series of plasma air purifiers was successfully developed.

In 2007, the experimental base - "UV Technology Research Institute" was established.

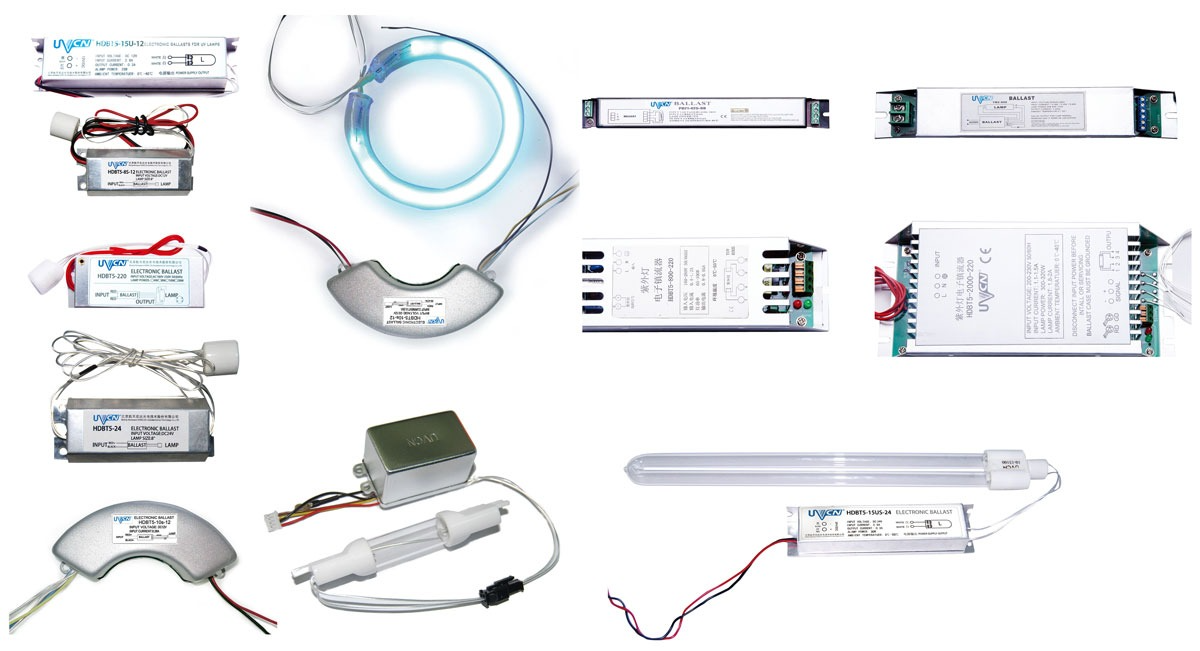

In 2008, the UV core component light source and dedicated power supply were successfully developed (several watts to 300 watts), with technical indicators leading domestically and catching up with international advanced levels.

In 2009, the "Special UV Light Source Special Production Line" was successfully developed.

In 2010, the "UV Radiation Oil Fume Purification System" was successfully developed.

In 2011, the core technology design scheme for the "ship ballast water treatment system" was completed, and key equipment and core components achieved phased results. Due to funding issues, this project serves as a technical reserve.

In 2013, some of the products developed and produced were exported to Europe and the United States;

In 2018, we developed special light sources for well-known domestic enterprises and obtained bulk orders with a one-time approval.

In 2019, the trial production of xenon lamps required by a domestic wafer fab achieved phased results. Complete the research and development of a new type of plasma purifier.

For decades, I have participated in and supervised multiple large-scale complex system projects and research projects, which has honed my overall design ability, command technical research ability, and technical organization and coordination ability. I have rich engineering experience and strong hands-on ability. I have excellently achieved "theoretical guidance for practice", provided technical reserves for greater challenges, and accumulated rich technical knowledge to strive for "industry leadership".

Years of scientific research and production practice have formed a unique technological style, and competitive advantages are beginning to emerge.

Dare to innovate, be good at innovation, and innovate quickly when undertaking technical projects.

Innovative

If China wants to become an innovative country, enterprises must become innovative enterprises. Zhang Runsong is sensitive to new technologies and has foresight. With a solid technical foundation, years of technical accumulation in large projects, and rich engineering design experience, he has enough confidence to challenge the world's advanced level;

Skilled in innovation

The designed products adhere to advanced technology, create "high-end", create "system performance optimization", and strive for excellence and cost-effectiveness.

For foreign advanced technology, it is not simply the introduction and imitation, nor the general system integration, but the "innovation" based on the introduction and absorption of its essence to create its own characteristic products.

Our product positioning and project approval principles are based on a clear market demand, with certain technical difficulties in achieving our goals. Through innovation, we aim to break through key technological bottlenecks and create high-end products. Transforming from 'imitation' to 'creation', creating good performance and cost-effectiveness, thus possessing a significant competitive advantage.

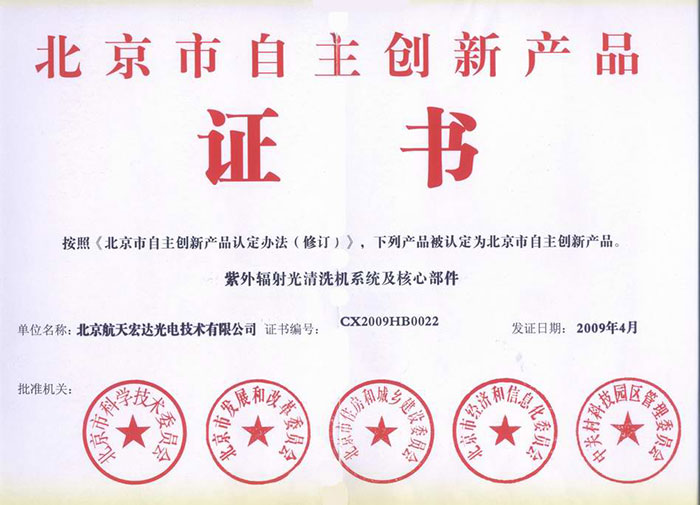

For example, the establishment of a light cleaning machine is a good demonstration. At the International Cleaning Engineering Forum exhibition, more than 90% of the products are chemical cleaning and ultrasonic cleaning (more than 300 companies), which belong to traditional industries. The person in charge of the Ministry of Information Industry encourages us to continue developing and industrializing this "high-end product", changing the current situation of "imitating" low-end products in China. In system design, more emphasis is placed on "applicability" and "differentiation", such as the creative idea of "self purification", making it more environmentally friendly and safe. The application of multiple sensors makes the system more optimized in terms of functionality, moderate in price, and can be better promoted, achieving optimality and cost-effectiveness. It can achieve the substitution of imports and optimize the export product structure, with a competitive advantage.

Rapid Innovation

For decades, I have led my team to develop many high-level projects:

For example, the "Gallium Arsenide Single Crystal Horizontal Growth System", from scheme demonstration, system design, production and development to the production of 10 qualified samples of "Gallium Arsenide Single Crystal Rod" using newly developed equipment (sent to the United States and certified by AXT) and passing the strict acceptance of the equipment by the United States, the entire cycle was only seven months. Under the leadership of Zhang Runsong, a team of 11 people successfully completed the task on schedule. As a layman in the field of "drawing single crystals", being able to complete an unprecedentedly difficult contract in such a short period of time has surprised and shocked the US side. We reversed the view of foreign companies at that time that "Chinese companies had low levels of expertise and lack of integrity" by using the fact that it was "impossible to achieve"; We have received recognition and praise from the US side for our advanced technology and integrity, and have been given the highest treatment and rewards.

Achieved 'advanced' through technological innovation; Through rapid innovation, we have won time and market share. As' pulling single crystals', we are outsiders; But with our diligent study and technological innovation, laymen have become experts, surpassing the "manual" of the "Colored Institute" with "intelligence", creating a "myth" of laymen becoming advanced. The company employees excitedly praised: our boss is the most innovative spirit.

Basic research and research on key common technologies enhance technological reserves and improve core competitiveness.

Zhang Runsong has always attached great importance to basic research and the development of key common technologies. For example, in order to successfully develop the light cleaning system, he initially developed special light sources and light source power supplies; In order to meet its technical specifications, a specialized testing equipment and analytical instrument - vacuum ultraviolet spectrometer - has been developed to enable quantitative testing and analysis of the light source (currently, domestic light source manufacturers have not conducted quantitative testing); At the same time, unique performance light source production equipment and typical process innovations have been developed, ensuring the competitiveness of core technologies.

Due to the higher technical specifications of the core components of ultraviolet technology (light source and supporting power supply) compared to general industries, and the difficulty in achieving the optimal matching of technical parameters between two different industries (light source and power supply). Therefore, foreign customers have cancelled their cooperation with existing foreign suppliers and chosen our core components,. Because our research and development institutions possess core competitiveness generated by core technologies.

Proficient in undertaking large-scale projects involving interdisciplinary, multi-disciplinary, and cross industry composite technologies.

Comprehensive technology and broad knowledge, able to leverage advantages in fields with a wide range of specialties such as optics, mechanics, and electronics. Proficient in interdisciplinary and cross disciplinary technology application for overall system design. For many years, we have persisted in developing interdisciplinary and cross disciplinary composite technologies. For example, the light cleaning machine involves many professions with large spans, such as special ultraviolet light sources, high-power light source power supplies, complex self-control systems and electric light sources, microelectronics, power electronics, automatic control, opto mechatronics integration, etc. Therefore, it has high technical difficulty and strong competitiveness. The developed product is a cross industry industrial composite.

The three sub items in the light cleaning system each have outstanding innovative points. The three major parts of special light source, electronic ballast and complete machine system have strong differences and incompatibility with the traditional industry, which shows its high added value and progressiveness technology. Has a strong competitive advantage in the market.

The major projects listed above, such as the "Gallium Arsenide Single Crystal Horizontal Growth System", "Light Cleaning Machine", and UV Core Components (Light Source and Power Supply), are composite technologies with a wide range of expertise and even cross industry capabilities. Due to their broad knowledge base, they highlight strong overall planning, design, and technical organization and coordination abilities; Capable of serving as the technical commander for large and complex projects.

Adhere to the independent style and core competitiveness of mastering core technologies and possessing intellectual property rights

Dare to challenge cutting-edge technologies and be sensitive to new technologies. In years of research and development practice, we adhere to our own path, learn from advanced technologies, and never simply imitate or "integrate" any project. We must have independent core competitiveness and form a unique style and characteristics.

For example, the "logging oblique precision gyroscope" (which transplants inertial guidance technology used in aerospace to oil exploration logging systems) draws on products from the United States. But it has achieved 'continuous testing'; The project 'Motor Controller' has achieved 'closed-loop control'. Each project has achieved digestion, absorption, and innovation.

The high-power ultraviolet light source power supply currently under development was purchased from a German brand sample, but the development exceeded its performance indicators.

At present, the application of ultraviolet technology in the field of environmental pollution control in China has not been vigorously promoted. Its core technology and components rely on imports and are expensive, which affects the promotion and application. Many workshop style small factories have small production scales, low levels, low investment in technological support, and slow technological progress. Due to the lack of control over core technologies, they can only do integration, which restricts the development of technology.

By increasing investment in research and development, effectively improving research and development capabilities, conducting in-depth research on the core content of ultraviolet technology, such as core components, complete machine products, and system equipment, and studying their matching relationships, achieving optimal results, and changing the situation of low-end core components, low functionality of complete machine products, and single system design technology; Improving core competitiveness through technological innovation means: achieving high-end core components, intelligent whole machine products, and a new height of composite system design, creating high value-added, low-cost good products; Promote the development of ultraviolet technology through innovation; And participate in international competition.

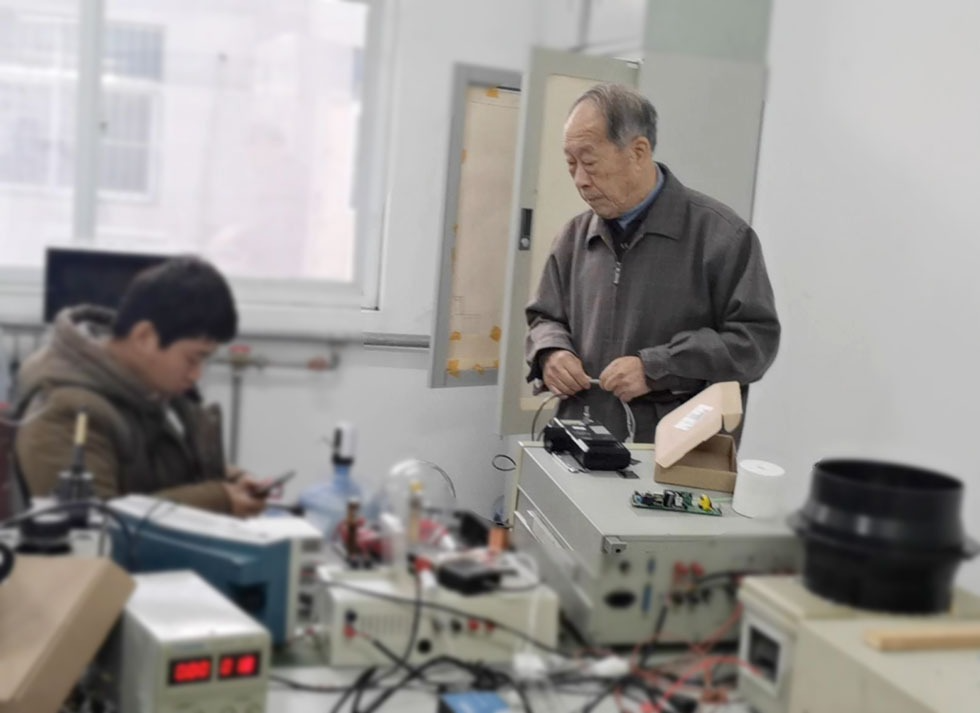

Developing successors and team building

Zhang Runsong is willing to work with young people and is good at cultivating "top teams", especially technical elites. Over the years, the master's, undergraduate, and college students I have led have achieved remarkable results both domestically and internationally. In practice, we have accumulated unique concepts and methods for educating people.

General Manager Zhang Runsong is over eighty years old. It is imperative and urgent to cultivate successors and build an elite team; The heavy responsibility lies on our shoulders, fulfilling our mission.

In order to accelerate the process of industrialization, strive to gather specialized talents, and solve the reserve source of the industrialization army, a school enterprise cooperation agreement has been signed with "Jingzhou Polytechnic Vocational College" - Electric Light Source major. "UV Technology Research Institute" has become an experimental base for graduates of the Electric Light Source major, and excellent graduates can be selected to work at our experimental base, solving the worries of human resources; It is also conducive to improving the quality of the industrial army. At the same time, attract outstanding talents from well-known foreign companies to work in the base.

Just so; But the growth of young power still requires a process and time. In order to achieve the goal, Comrade Zhang Runsong personally led the team to achieve "UV China, Purifying the World".

Perseverance and perseverance

In 2003, the project of "UV cleaning machine" was initiated, but it was rejected for purchasing foreign UV core components. However, the technical indicators of domestic products could not meet the requirements of the project system. Faced with the "technical blockade", it did not retreat and started from scratch without any foundation, independently developing (core components, complete system). From the first special ultraviolet light source experimental production line, the first key equipment for ultraviolet light source research and development - to the vacuum ultraviolet spectrometer, they have successively filled the gap in the domestic civilian field. We have developed our own equipment and instruments, cultivated a group of technical teams, explored unique production processes, and produced special ultraviolet light sources and power supplies that meet the requirements of the project system.

In 2006, as the inventor, the invention patent for the "UV radiation cleaning machine" was authorized,

In 2007, the "Ultraviolet Technology Research Institute" was established, which broke the passive situation of the core parts being "blocked". Because of our advanced technical indicators of light source and power supply and reliable performance, we have become the core parts supplier of some European and American air purifier brands.

After years of dedicated research and production practice in ultraviolet technology, its core components have gained a certain reputation both domestically and internationally.

For example, in the development process of the "Gallium Arsenide Single Crystal Growth System", the specially invited experts were unable to produce it. At a critical moment when the construction period was approaching, as an outsider in "pulling single crystals", they took the lead and shouldered the heavy burden, sticking to the single crystal furnace day and night. After dozens of days and nights of hard work, they finally used self-developed equipment to pull out qualified gallium arsenide level single crystals, and passed strict identification in the United States, creating a "miracle".

A positive and proactive work attitude, constantly learning and researching, and striving for progress. Over the past few decades, many achievements have been made in the research and development of new technologies, each of which has been achieved through tremendous hard work. For many years, I have been working for more than ten hours a day, timely tracking new technological developments, obtaining various related information, actively learning information technology, using new tools, etc., understanding cutting-edge technologies at home and abroad, and keeping up with them in a timely manner; Simultaneously maintaining a passion for innovation and entrepreneurship.

As he said in his speech on the listing of the New Third Board:

Although I am over 70 years old, my passion for innovation and entrepreneurship has never diminished, but has only grown stronger

'Eternal life, continuous innovation' has become his motto and inspires the entire team.

As a technological leader, his scientific attitude and pragmatic spirit are consistent expressions of his lifelong persistence and professional qualities.

Having been engaged in technical work for decades, I have developed a humble and cautious work style. I do not exaggerate my achievements, objectively evaluate products, and insist on continuous improvement and enhancement. For example, the light source provided to BIOZONE has a nominal lifespan of 8000 hours, and the customer's test result in Korea is 12000 hours; In our years of cooperation with clients, we have carefully self checked every issue (even minor ones) raised. Even if it is not our problem, we can provide technical guidance and advice in good faith. Our humble and cautious style has won the trust of clients and established a long-term stable and harmonious supply and demand relationship with them.

Gathering elites, the cohesion of unity and cooperation

After years of experience and accumulation, the technology is relatively comprehensive, knowledge has been greatly expanded, coupled with sensitivity to new technologies and quick access to information. It is able to track cutting-edge technologies and grasp their development trends. Through diligent learning and hard research, it can quickly respond to technical problems that need to be solved and find effective solutions with rich engineering experience. With these technical qualities, one can quickly find their elites in the required fields, and engage in in-depth communication, exploration, and cooperation, achieving mutual exchange and complementarity in technology, and striving for the best results. As a technical commander, in addition to having high technical skills, one should have good character, unite and collaborate to share achievements and benefits, and prioritize integrity.

For many years, regardless of the industry or field, we have been able to gather elites from all walks of life under the same goal, unite and cooperate, and create brilliance together.

Perseverance and determination to persevere until the end

The enterprise has been running for over 20 years since starting with 3000 yuan, and looking back at the journey it has taken, there have been successful stages of brilliance; We also took detours, but persevered and the company grew. Today, enterprises are facing enormous challenges and opportunities, and can continue to develop. Striving to become a "century old store", producing "high-quality products", and entering the high-end market is our long cherished wish. To pursue a career, one must persevere, regardless of everything, and persist until the end. In 1998, it received high praise and appreciation from the United States for its outstanding completion of the "Gallium Arsenide Single Crystal" project; And we sincerely invite you to join us in the United States. We were not moved by the favorable treatment and superior scientific research conditions offered by the United States; Declined the invitation to join AXT, and aspired to be a foreigner in the field he set foot in, contributing his whole life to rewriting "Made in China" and "Created in China".

Today, the environmental situation is severe; Our goal is to provide Chinese people with fresh air, clean water, and safe food.

The heavy responsibility lies on our shoulders, fulfilling our mission and continuing to move forward.

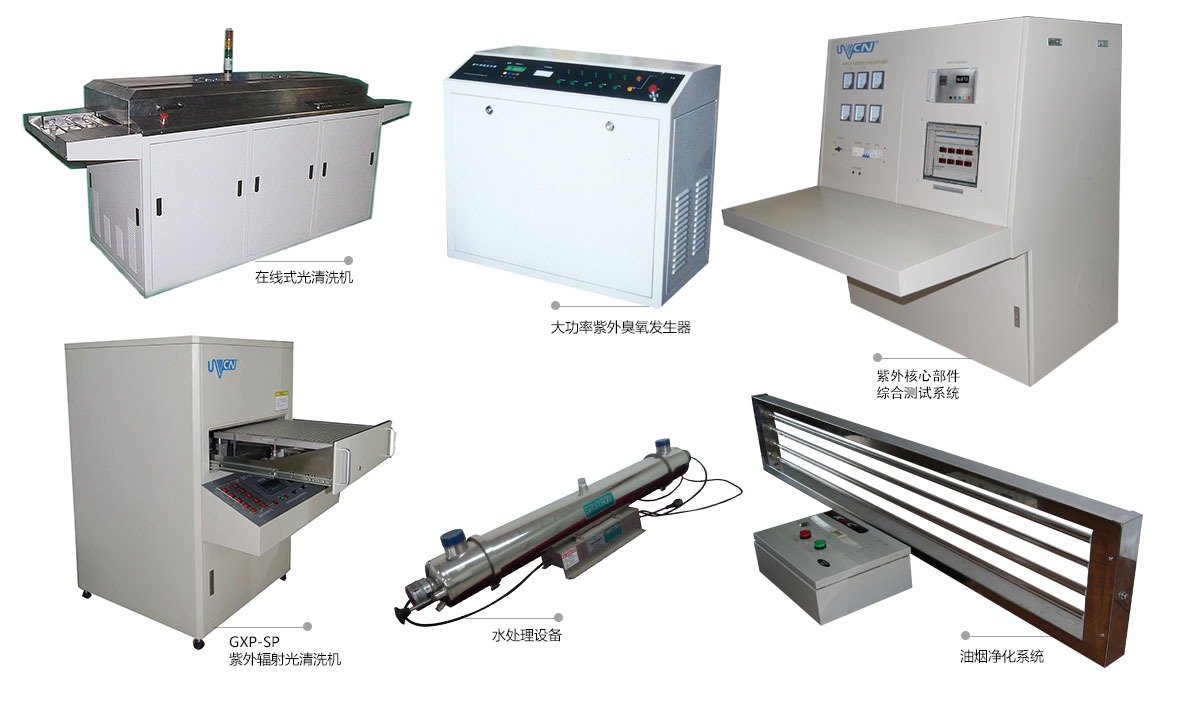

Product Category:

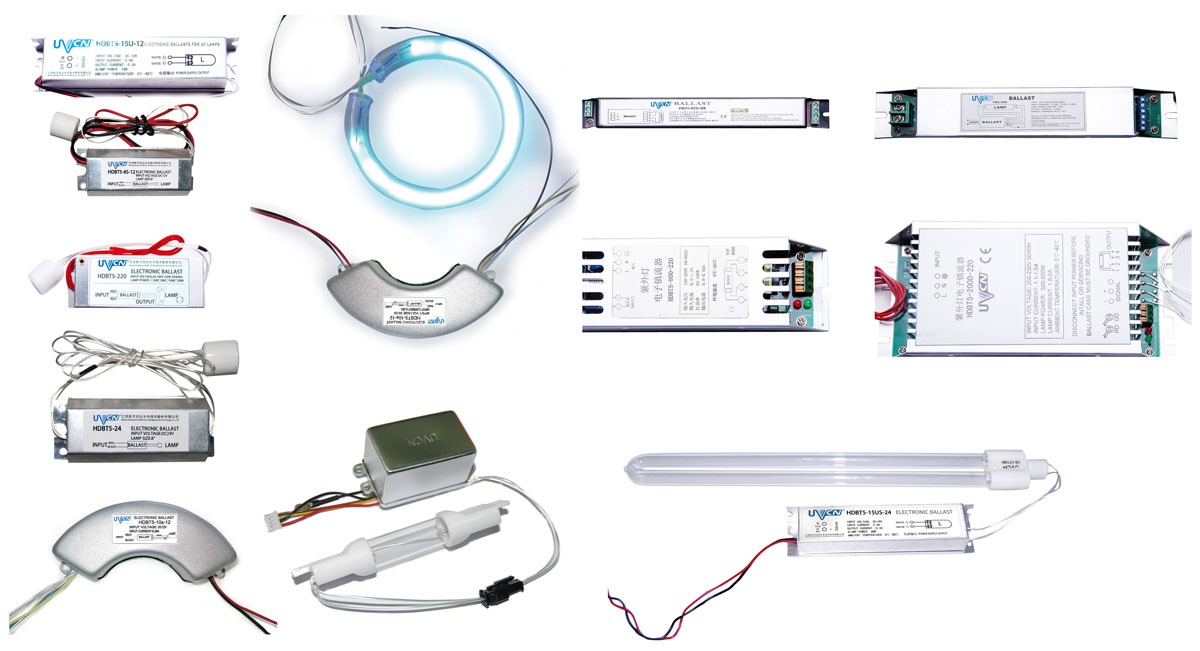

1. UV core components (UV core technology) products: special light sources and supporting power supplies (series)

2. Whole machine product: Optical plasma air purifier product (series)

3. UV radiation cleaning machine system products (series)

4. Oil fume purification system products

5. Central air conditioning purification system (product)

6. Ship ballast water pollution control system

7. Relevant identification (detection) system: vacuum ultraviolet spectrometer (system)

8. Comprehensive detection system for ballast water

9. Application system specific core components: dedicated sensor series, dedicated ultraviolet illumination sensor, dedicated flow sensor, dedicated ozone concentration sensor, dedicated pressure sensor, dedicated turbidity sensor

10. Key equipment for special ultraviolet light source production line

Product positioning:

● Special UV light source and power supply series products

● Light cleaning machine series products

● Light plasma air purification series products

● Professional complete solutions and engineering implementation for air and water pollution control

Technical strength:

● Aerospace Hongda has its own UV technology research institute;

● We have our own research and development laboratory, as well as an experienced team of research and development experts (a significant portion of whom are senior scientists from the Chinese Ministry of Space).

● The vacuum ultraviolet spectrometer independently developed by the company can detect wavelengths up to 50 nanometers and below, with a resolution of up to 0.02 nanometers, ensuring that we can manufacture high-quality light source systems.

● Our strong research and development capabilities have made us a core technology, component, and complete machine product supplier

The products designed by Aerospace Hongda adhere to maintaining high-end technology, optimized system performance, and high cost-effectiveness. For foreign advanced technology, it is not simply the introduction and imitation, nor the general system integration, but the "innovation" based on the introduction and absorption of its essence to create its own characteristic products. Our product positioning and project approval principles are based on a clear market demand, with certain technical difficulties in achieving our goals. Through innovation, we aim to break through key technological bottlenecks and create high-end products. Transforming from 'imitation' to 'creation', creating excellent performance and price ratios, is the key to having a strong competitive advantage. In system design, more emphasis is placed on "applicability" and "differentiation", such as the creative idea of "self purification", making it more environmentally friendly and safe. The application of multiple sensors optimizes the system's functionality, is reasonably priced, and can be better promoted. It can achieve the substitution of imports and optimize the export product structure, with a competitive advantage.

For decades, the Aerospace Hongda technology team has developed many high-quality projects:

In 1998, a gallium arsenide single crystal horizontal growth system was developed. In 2001, a "precision gyroscope for logging" was successfully developed. In 2003, a light cleaning machine was approved. In 2012, a mobile transportation air purification system was developed.

Basic research and research on key common technologies enhance technological reserves and improve core competitiveness

Our company has been engaged in comprehensive research and development of key links in the UV technology industry chain since 2003. We integrate light sources (core components), power supplies (core components), complete machines, and application systems into our company. Although we have invested heavily in the early stages, our starting point is high, highlighting our competitive advantage in the market and our ability to grow rapidly. We aspire to eventually form a strategic emerging industry. The company established the "UV Technology Research Institute" in 2007 and was recognized as a "research and development institution" by the Beijing Municipal Science and Technology Commission. We have clarified our product positioning and development direction, and are committed to developing core components with independent intellectual property rights, as well as high-performance and cost-effective application products. Many of our individual core components, complete machines, and system design results are not far behind those of foreign countries. To this end, we have increased our research and development investment in key technologies across the entire industry chain. After more than a decade of accumulation and development, our company has now reached a professional level in the application of ultraviolet technology in the industry.

Interdisciplinary, multidisciplinary, and cross industry composite technology

The major projects listed above, such as the "Gallium Arsenide Single Crystal Horizontal Growth System", "Light Cleaning Machine", and UV Core Components (Light Source and Power Supply), are composite technologies with a wide range of expertise and even cross industry, highlighting the strong technological advantages of Aerospace Hongda. Aerospace Hongda has always attached great importance to basic research and the development of key common technologies. For example, in order to successfully develop the light cleaning system, special light sources and light source power supplies were developed in advance; In order to meet its technical specifications, a specialized testing equipment and analytical instrument - vacuum ultraviolet spectrometer - has been developed to enable quantitative testing and analysis of the light source (currently, domestic light source manufacturers have not conducted quantitative testing); At the same time, unique performance light source production equipment and typical process innovations have been developed, ensuring the competitiveness of core technologies.

Comprehensive technology, able to leverage advantages in fields with large professional spans such as optics, mechanics, and electronics

Proficient in interdisciplinary and cross disciplinary technology application for overall system design. For example, the light cleaning machine involves many professions with large spans, such as special ultraviolet light sources, high-power light source power supplies, complex self-control systems and electric light sources, microelectronics, power electronics, automatic control, opto mechatronics integration, etc. Therefore, it has high technical difficulty and strong competitiveness. The developed product is a cross industry industrial composite. The three sub items in the light cleaning system each have outstanding innovative points.

The three major components of special light sources, electronic ballasts, and complete machine systems have strong differences and incomparability with traditional industries, demonstrating their high added value and technological advantages.

Adhere to the independent style and core competitiveness of mastering core technologies and possessing intellectual property rights.

Aerospace Hongda Company dares to challenge cutting-edge technologies and is sensitive to new technologies. In years of research and development practice, we adhere to our own path, learn from advanced technologies, and never simply imitate or "integrate" any project. We must have independent core competitiveness and form a unique style and characteristics. For example, the "logging oblique precision gyroscope" (which transplants inertial guidance technology used in aerospace to oil exploration logging systems) draws on products from the United States. But it has achieved 'continuous testing'; The project 'Motor Controller' has achieved 'closed-loop control'.

Each project has achieved digestion, absorption, and innovation. The high-power ultraviolet light source power supply currently under development was purchased from a German brand sample, but the development exceeded its performance indicators. At present, the application of ultraviolet technology in the field of environmental pollution control in China has not been vigorously promoted. Its core technology and components rely on imports and are expensive, which affects the promotion and application. Many workshop style small factories have small production scales, low levels, low investment in technological support, and slow technological progress. Due to the lack of control over core technologies, they can only do integration, which restricts the development of technology.

By increasing investment in research and development, effectively improving research and development capabilities, conducting in-depth research on the core content of ultraviolet technology, such as core components, complete machine products, and system equipment, and studying their matching relationships, achieving perfect results, and changing the situation of low-end core components, low functionality of complete machine products, and single system design technology;

Improving core competitiveness through technological innovation means: achieving high-end core components, intelligent whole machine products, and a new height of composite system design, creating high value-added, low-cost good products; Promote the development of ultraviolet technology through innovation; And participate in international competition.

The scientific research management system applicable to special ultraviolet light sources is boldly inherited and innovated.

By innovating the R&D institution system, we will focus on key elements in the industrial chain, such as special ultraviolet light sources, specialized supporting power supplies, application products, and application systems; Ultimately, we will develop the entire industry chain. The application field of UV technology projects is environmental protection. Specifically, it is the treatment of air and water pollution. This is a massive interdisciplinary system engineering project. UV technology is one of the important means among them. Due to its high efficiency and the advantage of no secondary pollution; Make it grow rapidly. China has entered a period of mandatory implementation of new drinking water standards and rapid changes in environmental protection situations such as air purification requirements such as PM2.5; It will inevitably lead to a huge demand for ultraviolet technology. This technology is still in its infancy in China. But with a history of nearly a hundred years abroad, the operating mode is relatively mature, and the enterprises that have formed a scale are almost engaged in the "whole industry chain".

① At present, China is developing in isolated areas of the industrial chain. Due to the wide range of professions and industries in this industry chain, we do not understand each other. It is difficult to develop an application system with a certain level of expertise in a single technical field,

② The development of key components such as special ultraviolet light sources and power supplies is difficult to meet the requirements of the system. Enterprises engaged in application systems, on the other hand, do not understand the former technology, making it difficult to propose precise requirements and match them.

③ Light source power supply is another field that is different from the light source industry. The coordination among the three parties is even more complicated, as those who work with light sources do not understand power sources, and those who work with power sources do not understand light sources.

④ The existing system is difficult to ensure that the achievements of light sources and power sources are exclusively enjoyed by system enterprises, and intellectual property rights cannot be effectively protected. The core content of ultraviolet technology includes light source, power supply, and application system. Being three different industries; There is a very close matching relationship between them. Only when the "three in one" (or N-in one) system is completed by one enterprise to complete the entire industrial chain, can the best matching of each key link in the industrial chain be achieved, and the prominent contradictions in the coordination of each link be overcome to enable UV technology innovation and rapid industrial development to meet the major needs of China's environmental situation. The successful experience of large enterprises in foreign counterparts has proven this point. To catch up with and surpass the world level as soon as possible, it is necessary to establish an industrial chain and innovate the system.

Focusing on independent research and extensive cooperation, gathering elites to achieve goals.

Independent research and development: With ultraviolet technology as the core technology and special ultraviolet light sources and supporting power supplies as the core components of the plasma technology, we closely follow the world's professional level, break through cutting-edge key technologies, actively innovate, highlight differences and characteristics, create our own characteristics and advantages in application, and actively participate in global competition. Wide cooperation: In this application field, in addition to innovating core technologies, it also involves many related professional technologies and joint development with universities or research institutions in related fields. The successful development of the "Vacuum Ultraviolet Spectrometer" is the result of cooperation with the "Changchun Institute of Optics and Fine Mechanics", which solves the quantitative detection and analysis of special light sources and enhances our position in the industry. We are currently actively preparing to establish a 'laboratory'. For example, the demonstration application of ultraviolet technology in the field of "emission reduction" and environmental protection has cooperated with the Institute of Electric Light Source at Fudan University in Shanghai, the Institute of Chemical Engineering at Beijing University of Petroleum, and the Department of Optical Engineering at Beijing Institute of Technology, among others, and signed agreements for industry, academia, and research. This year, we will increase our cooperation efforts to promote the transformation of achievements.

For many years, enterprises have adhered to technological innovation and invested heavily in research and development, with the highest reaching over 70% and the lowest reaching over 10% of total revenue. This investment is used to increase research and development equipment, instruments, patent applications, purchase books, materials, and participate in necessary academic exchange activities, strengthen technical team building, and continuously improve research and development capabilities. For many years, Aerospace Hongda has been fearless and unafraid of difficulties on the path of innovation. In 2003, the project of "UV cleaning machine" was initiated, but it was rejected for purchasing foreign UV core components. However, the technical indicators of domestic products could not meet the requirements of the project system. Faced with the "technical blockade", it did not retreat and started from scratch without any foundation, independently developing (core components, complete system). No equipment, no instruments independently developed. From the first special UV light source experimental production line to the first key equipment for UV light source research and development - to the vacuum UV spectrometer. We have developed our own equipment and instruments, cultivated a group of technical teams, explored unique production processes, and produced special ultraviolet light sources and power supplies that meet the requirements of the project system. Obtained the invention patent for "UV radiation cleaning machine" in 2006. In 2007, the "Ultraviolet Technology Research Institute" was established, which broke the passive situation of the core parts being "blocked". Because of our advanced technical indicators of light source and power supply and reliable performance, we have become a supplier of core parts of well-known European and American brands of air purifiers. After years of dedicated research and production practice in ultraviolet technology, its core components have gained a certain reputation both domestically and internationally.

In years of scientific research and production, Aerospace Hongda has adhered to a scientific attitude and a pragmatic spirit.

In our years of cooperation with clients, we carefully self examine every issue (even minor ones) raised. Even if it's not our fault, we provide technical guidance and advice in good faith. With humility and caution, we have won the trust of our clients and established a long-term stable and harmonious supply and demand relationship with them.

Gathering elites and fostering cohesion through unity and cooperation. After years of experience and accumulation, the technology is relatively comprehensive, knowledge has been greatly expanded, coupled with sensitivity to new technologies, quick access to information, and the ability to track cutting-edge technologies and grasp their development trends. It can quickly respond to technical problems that need to be solved and find effective solutions based on rich engineering experience.

To engage in in-depth communication, exploration, and cooperation with other professional fields, in order to achieve mutual technical exchange, complementarity, and strive for the best results. Unity and cooperation result sharing, benefit sharing, integrity first.

Perseverance and determination to persevere until the end

The enterprise has been running for over 20 years since starting with 3000 yuan. Its development has been from scratch, from small to large. Looking back at the journey it has taken, there have been successful stages of brilliance; We also took detours, but persevered and the company grew. Today, enterprises face enormous challenges and opportunities, and continue to develop. Adhering to producing high-quality products and maintaining technological innovation are the advantages of Aerospace Hongda.

Registered enterprise in Fengtai Science and Technology Park in 1994: Beijing Hongyuan Guang Electromechanical Measurement and Control Equipment Research Institute

From 1997 to 2001, Beijing Aerospace Hongyuan Science and Trade Co., Ltd. was established to undertake research and development projects.

In the early stage of the company's entrepreneurship, it mainly cooperated with relevant units of the Ministry of Aerospace for military product processing, ground testing equipment, cables and other products.

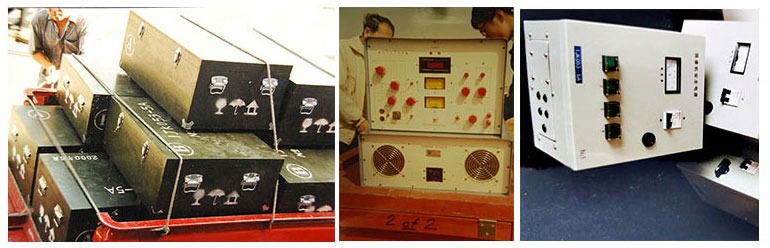

In 1997-98, we undertook the development project of the "Gallium Arsenide Horizontal Single Crystal Growth System" in the United States

This project is a large-scale collaboration between the Nonferrous Metals Research Institute (Research Silicon Valley) and American Xtal Technology (AXT), a publicly listed company in Silicon Valley, USA, to explore long-term plans for cooperation. Due to the industry advantages of Aerospace Hongda and the rich engineering experience and practical ability from aerospace background, we dared to participate in the competition, and ultimately AXT signed a contract with our company. And completed the system design, production, experimentation, and commissioning as quickly as possible (with a contract period of seven months), and used its equipment to pull out ten qualified single crystal rod samples. The qualification rate reaches 80%.

Aerospace Hongda has completed the contract as scheduled and passed the appraisal of American peer experts. At that time, it was a sensation at AXT company; Completing this project in such a short period of time is rare in China.

Due to the overall level of system engineering exceeding expected requirements, the equipment of the entire system has been redesigned to achieve closed-loop automatic control of the entire process of single crystal growth. (However, the domestic "Nonferrous Industry Institute" was manual, and this technology was blank abroad at that time. Aerospace Hongda was the first to apply computer technology to this field and improve it.)

As a layman in the field of "pulling single crystals", Hongda Company is able to meet and exceed the technical requirements of the United States (which should be said to be very demanding), and its partners are very surprised (even if American companies have a certain scale and technical strength, it is difficult for them to complete such a difficult project in such a short period of time). AXT Company in the United States fully recognizes Hongda Company's professional and technical strength, especially its multi-disciplinary and cross disciplinary technical competitiveness and comprehensive quality.

This technology has been successfully transferred by Aerospace Hongda to AXT company, while also assisting them in successfully building factories in China. The completion of this project is of great significance to Aerospace Hongda, as it has accumulated financial reserves for future research and development; More importantly, the team has been trained through practical experience.

In 1999, a "motor controller" was developed for AXT company and 300 sets were supplied. As an exported product, the company adheres to quality first and strict management. The personnel have years of experience in military production and have set a record of zero anti repair rate, receiving praise from the US side. Subsequently, due to the impact of the economic crisis on AXT's expansion plan, subsequent contracts were unable to continue.

In 2001, the "Precision Gyroscope for Logging" was successfully developed. Trial production of 2 sets was successful, with accuracy meeting standards and achieving "continuous testing". At that time, it had a certain influence in the field of logging technology, and users were also quite satisfied. During the trial at Zhongyuan Oilfield, good feedback was provided. This project is to apply inertial positioning technology from spacecraft to logging technology. The flight time of the aircraft is very short and there is no issue with its lifespan, while further improvements are needed to overcome the lifespan issues in civilian logging and ensure its normal operation under high temperature environments in deep wells. At that time, on the one hand, the domestic key components were not yet up to standard (imported ones were not available), and more importantly, further research and development required a large amount of funding. Therefore, this technology was suspended and restarted at an appropriate time as a technical reserve.

In 2000, Aerospace Hongda adjusted its thinking and decided to develop products with independent intellectual property rights, taking the initiative in market competition.

In May 2002, Beijing Aerospace Hongda Optoelectronic Technology Co., Ltd., a high-tech enterprise, was registered in Haidian Park.

The process of independent entrepreneurship in the field of ultraviolet technology and applications began in 2003.

The project is to develop a "UV radiation cleaning machine" and establish a three in one system of "light source, power supply, and complete machine".

The whole machine is equipped with a light source (relying on imports at that time), an electronic ballast (other companies used inductive type at that time), and a prototype of the light cleaning machine principle.

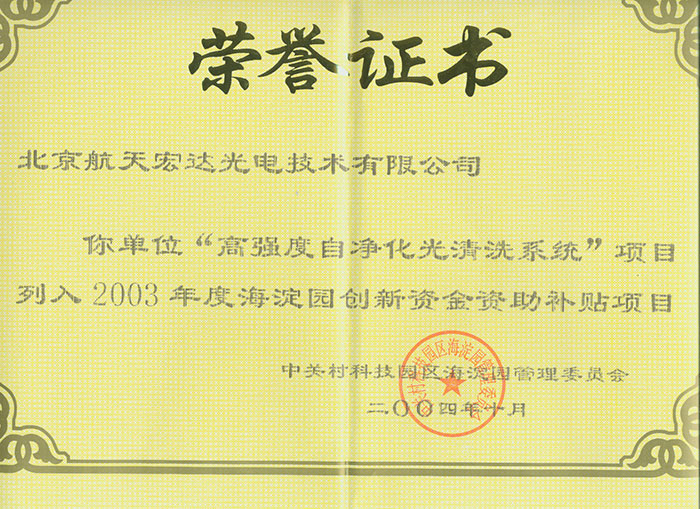

At the end of 2003, it participated in the exhibition and stood out among over 300 exhibitors in the cleaning industry with its unique "light cleaning" feature. Although displayed in the corner, it has received great attention from politicians such as the International Environmental Protection Agency and the Ministry of Information Industry. After the meeting, the Ministry of Information Industry led more than ten enterprises to participate (500000 yuan) in forming a clean technology innovation "consortium" and invited us to join. Due to financial difficulties, we declined the invitation and continued to start our own business.

Established a professional special light source production team in 2004

The company's successfully developed plasma tube adopts innovative technology to enhance the spectral line intensity, and uses a new type of quartz glass tube to improve the penetration ability of ultraviolet rays; The sterilization and disinfection effect has been greatly improved; It has been well applied in anti epidemic and epidemic prevention products

Since 2003, the company has been committed to the research of ultraviolet technology, starting with the "ultraviolet radiation light cleaning" technology introduced from abroad at that time. The original plan was to start with system integration, but later it was found that the core components, special ultraviolet light sources, and power supplies could not be solved, and domestic technical indicators could not be met. The purchase of foreign light sources was also "banned" and technically blocked, which led Aerospace Hongda to independently develop its own core products: starting from the core technology of ultraviolet, the core components of special ultraviolet light sources and supporting special power supplies, and finally shifting to the research and development of application systems.

The specialized light source for the light cleaning machine, which was successfully developed in 2004, was unable to be identified and tested by the Chinese Institute of Metrology. In order to conduct in-depth research on ultraviolet technology and fill the domestic gap in "deep ultraviolet detection", Aerospace Hongda has initiated the development of a "vacuum ultraviolet spectrometer".

The successful development of the spectrometer provides a scientific basis for the innovation of ultraviolet and plasmonic technology, and is also an important advantage in industry competition.

Aerospace Hongda's independently developed vacuum ultraviolet spectrometer

In 2004, Aerospace Hongda independently developed a vacuum ultraviolet spectrometer

In the same year, we began providing core components for domestic and foreign manufacturers of air purifiers, represented by "Zhongmai Group" domestically and BIOZONE internationally

In 2005, the project was initiated to develop application products such as "plasma air purifier" and "water purifier"

From 2008 to 2010, the "UV Technology Research Institute" (branch) was established and recognized by the Beijing Municipal Science and Technology Commission as a "research and development institution", further establishing the product positioning and research and development direction centered on UV technology and applications. After 3 years of effort, a production line for UV core components adapted to small-scale production has been built, forming a unique production process and core component products. The whole machine products have expanded to the fields of environmental protection and people's livelihood; The process of industrialization has begun.

Production line construction (key production of light sources and power supplies, research and development equipment) was carried out from 2006 to 2007.

In March 2011, the "restructuring" was completed and "Beijing Aerospace Hongda Optoelectronic Technology Co., Ltd." was established

On August 30th of the same year, it was listed on the Shenzhen Stock Exchange (430096) and entered the "New Third Board".

1. Technological transformation of production equipment - The automation of major equipment has been completed, such as "round row cars" and "head installation machines", which have strong competitive advantages in the industry. Production capacity will increase by 5-10 times; The quality will also be relatively stable. Can effectively solve the problem of "light source technicians".

2. The production process is stable and the products are basically standardized, with a decrease in scrap and repair rates, and stable quality.

Preparation for product industrialization from 2011 to 2014

Based on the product positioning and market development direction of market segmentation:

Mobile transportation air purification system (cars, subways, high-speed trains, etc.), indoor air purifier series, indoor air quality control system.

Complete the research and development of the latest intelligent plasma air purifier from 2017 to 2019