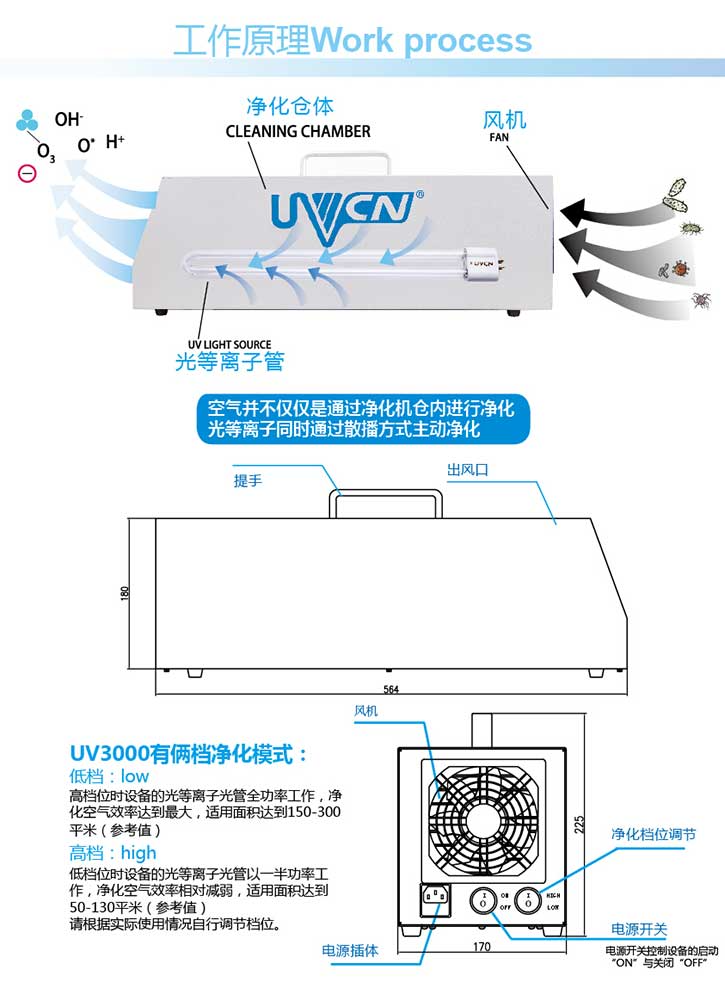

Product Introduction:

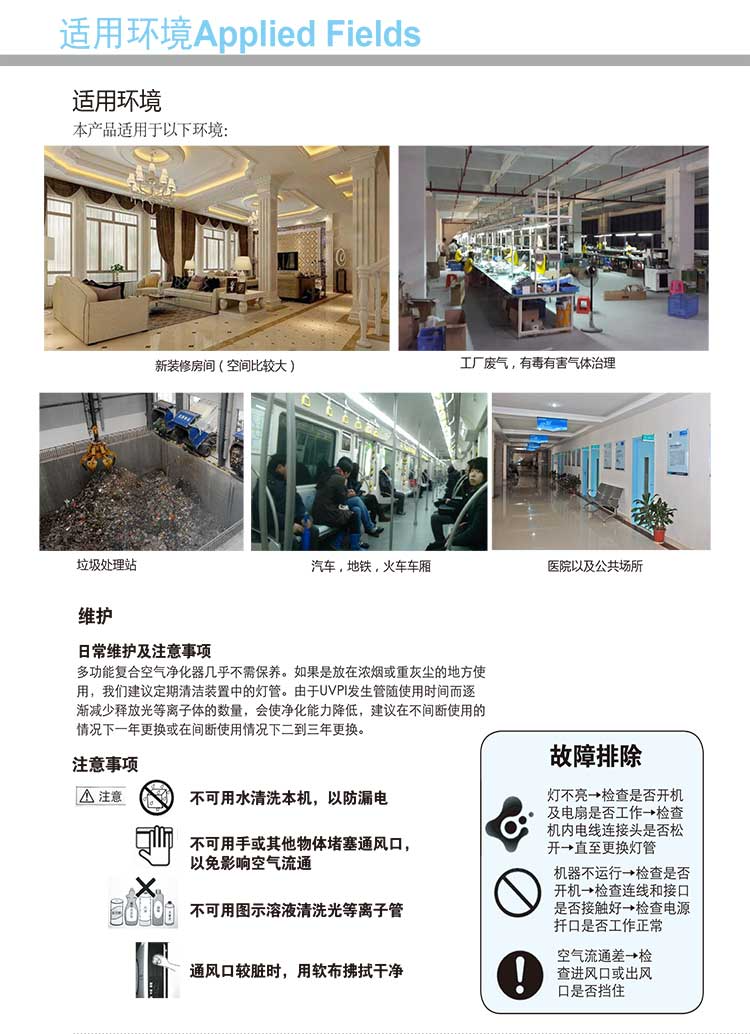

Handheld, high-power, faster purification and disinfection speed, metal shell industrial style, simple design, easy to operate. UV3000 is suitable for: used in consultation rooms, wards, hotels, factories to quickly purify the air, disinfect and deodorize. Sterilization function: switching between 2nd level concentration of reactive oxygen species

technical parameter

Product parameters:

Size: 564x170x225mm Net weight: 4.8kg

Color: Grey white

Material: All metal Rated input voltage: 220 V AC

Rated output power:<76w

Input frequency: 50/60 Hz Rated input current: 0.43 A

Product Features:

Extremely low energy consumption. No need for filter material or battery replacement, extremely low maintenance requirements. Reduce economic and labor costs. Simply replace the lamp every 12 months to achieve optimal results.

Effectiveness study: UVCN technology has been tested to achieve the following removal effects:

Surface Escherichia coli removal rate>99.999%

Surface Listeria removal rate>99.999%

Surface Salmonella removal rate of 100%

The removal rate of bacteria in the air is 98.24%

100% removal rate of hydrogen sulfide in the air

Avian influenza virus removal rate>99.999

Para influenza virus removal rate>99.999

Sterilization and disinfection efficiency: 99%/10 minutes

Natural bacterial extinction rate: 83.9%

Formaldehyde removal rate: 93.7% Benzene removal rate: 92.50%

Ammonia removal rate: 92.1%

TVOC removal rate: 93.7%

Main technical parameters:

Active ingredients: UVC+UVD+03+0+0*

Working temperature: -4 ° C -45 ° C

Environmental humidity: 0-85%

Continuous working air outlet airflow: 7m/s

Ventilation rate: 400-420 m3/h

Effective applicable area: 200-300m2 (reference value)

Air outlet noise:<80db

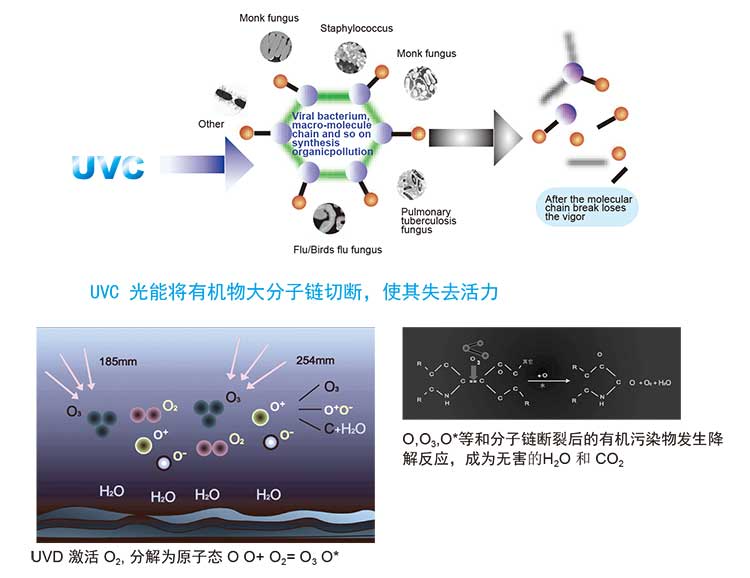

Photoplasma technology

Purifying Photo Plasma technology is a type of advanced photochemical reaction technology used for purification

Advanced oxidation degradation technology, photoplasma has the following energy compositions: dual wavelength (UVC, UVD) ultraviolet light+(photoactivation) → pure ozone (O3)+atomic oxygen (O)+ground state oxygen (O *). Through a special ultraviolet light source with two wavelengths, a series of powerful bactericidal and disinfecting photoplasma clusters can be generated, collectively referred to as photoplasma.

As is well known, the main elements of all organic pollutants (bacteria, viruses, formaldehyde, ammonia, benzene, TVOC, etc.) are H and C (carbon and hydrogen), and their molecular structures are relatively stable. The basic principle of purification and degradation using photoplasma is that organic compounds (hydrocarbons) under specific wavelengths (UVC) and specific intensities of ultraviolet radiation undergo photosensitive processes, that is, after the molecules of organic compounds absorb the energy of specific wavelengths of photons, the molecular chains are torn and decomposed into ions, free atoms, excited molecules or neutral molecules; Meanwhile, under specific wavelengths (UVD) and intensities of ultraviolet radiation, oxygen molecules (O2) in the air absorb photon energy and transform into ozone (O3), atomic oxygen (O), and ground state oxygen (O *); These elements have very active chemical properties and strong oxidizing effects. They are strong oxidants that can completely oxidize the photosensitive decomposition products of organic compounds into volatile harmless gases such as water vapor (H2O) and carbon dioxide (CO2), achieving the goal of thoroughly removing pollutants.

Compared with other traditional purification methods, this purification result is clean, thorough, residue free, and does not cause secondary pollution.

User feedback:

In the exhibition hall of the garbage treatment plant, due to excessive formaldehyde and strong odor, I bought two UV3000 machines

The odor is completely gone, and the formaldehyde has been thoroughly treated

Quickly disinfect newly renovated homes to remove formaldehyde during the epidemic period