Product Introduction:

The company has the practical ability to cross industries, multiple disciplines, and respond quickly. It can leverage its advantages in fields with large professional spans such as optics, mechanics, and electronics. It is adept at conducting interdisciplinary system overall design, sensitive to new technologies, and forward-looking. The products it creates maintain technical advantages. The company has always prioritized quality and implemented strict management. Since 2001, the company has focused on the development and purification of special light sources, and has successively developed vacuum ultraviolet spectrometers, light cleaning machines, special light source power supplies, series of air purifiers, and water treatment products. Special light sources have been adopted by many domestic and foreign enterprises, and vacuum ultraviolet spectrometers have obtained national invention patents. In 2003, they were awarded the Haidian Park Innovation Fund.

Technical parameters:

The company has its own production and manufacturing base and has passed ISO 9000 quality system certification. Some products have also passed RhoS certification; TUV-GS and other certifications. The company adheres to independent innovation; Not only has it received rewards from government departments, but it has also gained recognition from customers both domestically and internationally.

Product Features

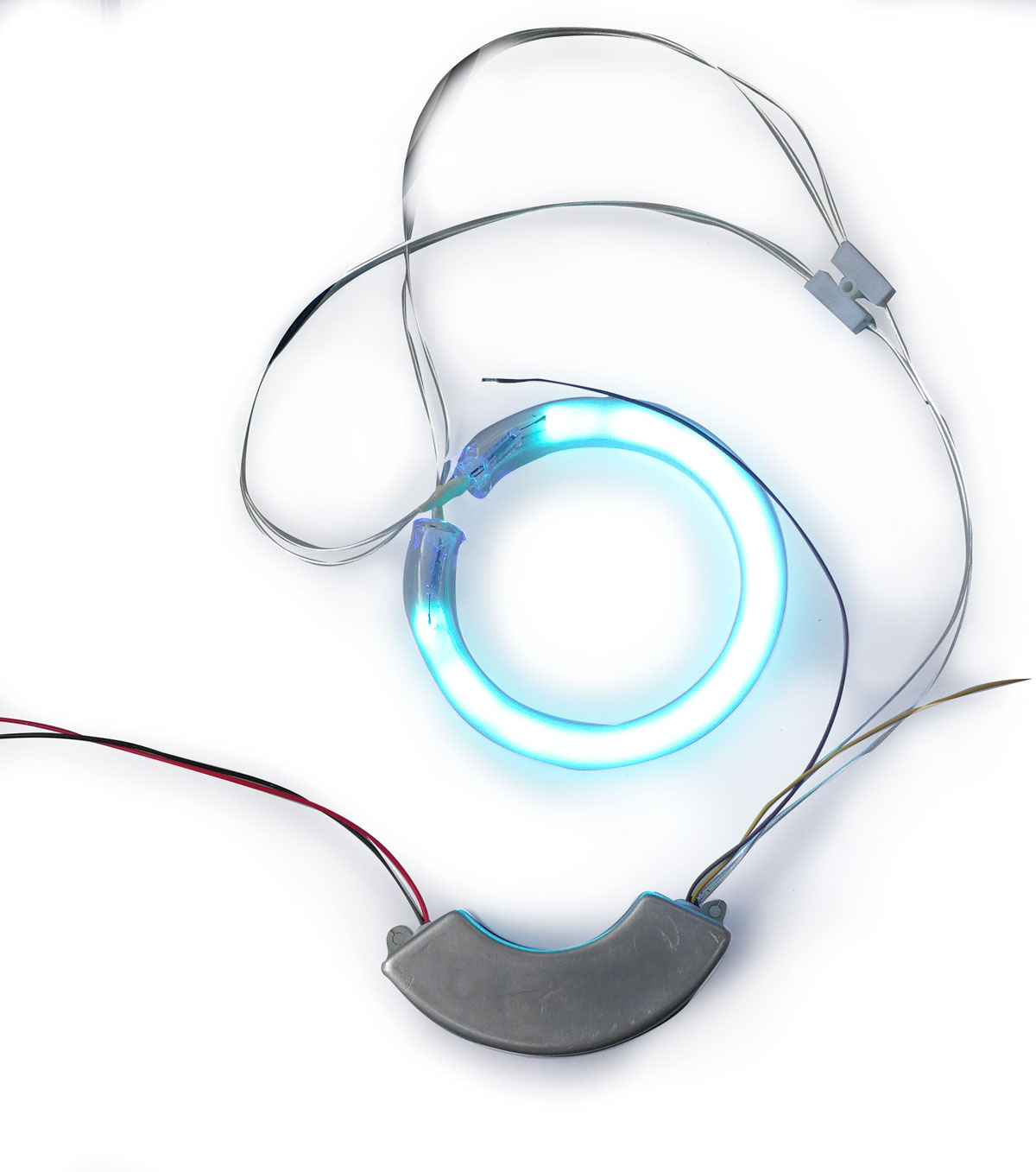

Can produce dual wavelengths: 185nm and 254nm. We can customize the production of UV lamps with different wavelengths according to the specific needs of customers.

To ensure stable performance of UV lamps, all lamp tubes are made of quartz material

To ensure the conductivity of the pins, all UV lamps use gold-plated pins

UV lamps can be customized according to specific parameters of the customer, such as power, current, external dimensions, and shape.

L company not only provides high-quality ultraviolet lamps, but also produces matching electronic ballasts. Our ballasts not only meet the needs of conventional ultraviolet lamps, but also can be customized with special voltage ballasts according to customers' specific requirements.

Performance of Aerospace Hongda Light Source

1. Gold plated lamp pins are used, and manual welding is used at the welding points, with fine craftsmanship.

2. The lamp head adopts ceramic glaze, which increases the hardness, oxidation resistance, smoothness and durability of the lamp head.

3. The exhaust temperature reaches 800 degrees. Thoroughly exhaust, no suction agent, high transparency inside the tube, and not easily blackening

4. The mercury content of the lamp tube is 2.6mg, while the EU standard is 3mg, which is more environmentally friendly.

5. The production and use of solid mercury have solved the problems of light decay and environmental pollution.

6. Direct communication can work normally.

7. Complete variety, supporting customization

8. Long term cooperation with internationally renowned enterprises

Advantages of Aerospace Hongda:

Aerospace Hongda has its own UV technology research institute;

Having its own R&D laboratory and an experienced team of R&D experts

The vacuum ultraviolet spectrometer independently developed by the company can detect wavelengths up to 50 nanometers and below, with a resolution of up to 0.02 nanometers, ensuring that we can manufacture high-quality light source systems.

Matching of UV light source and dedicated ballast:

It is recommended to pair the UV lamp with the UV specific ballast independently developed by UVCN Aerospace Hongda when purchasing.

Before being launched on the market, the Aerospace Hongda ballast was able to match UV lamps through repeated testing,

Improve the working efficiency of ultraviolet lamps, which have been tested by foreign users and have a lifespan of over 12000 hours.

Testing and after-sales service:

Before leaving the factory, every product of Aerospace Hongda undergoes detailed data recording and testing, greatly improving the stability of customers' products. Within one year from the date of purchase, there is a one-year warranty. In case of any quality problems caused by human factors, free replacement is available. (When using UVCN brand light source and ballast together, enjoy warranty service)

The special ultraviolet light sources of UVCN include low-pressure mercury lamps and high-pressure mercury lamps.

Widely used in fields such as sterilization and disinfection, air purification, water treatment, ultraviolet (UV) curing, light cleaning, surface treatment, etc,

The company produces ultraviolet light sources with power ranging from 4W to over 300W, and lamp tube diameters ranging from 6mm to 25mm,

Dual wavelength ultraviolet lamps can be produced, and different specifications of lamps can be customized according to user needs:

L-type, S-type, N-type circular lights, etc

Aerospace Hongda Special UV Light Source Professional User Report

Aerospace Hongda's independently developed special light sources have a very high reputation in the industry and are mostly used in national research institutions and projects.

User reports and feedback on the use of ultraviolet core components produced by Aerospace Hongda:

State Key Laboratory of Rare Earth, Peking University

State Key Laboratory of Bioelectronics, Southeast University

Shandong Institute of Marine Instruments

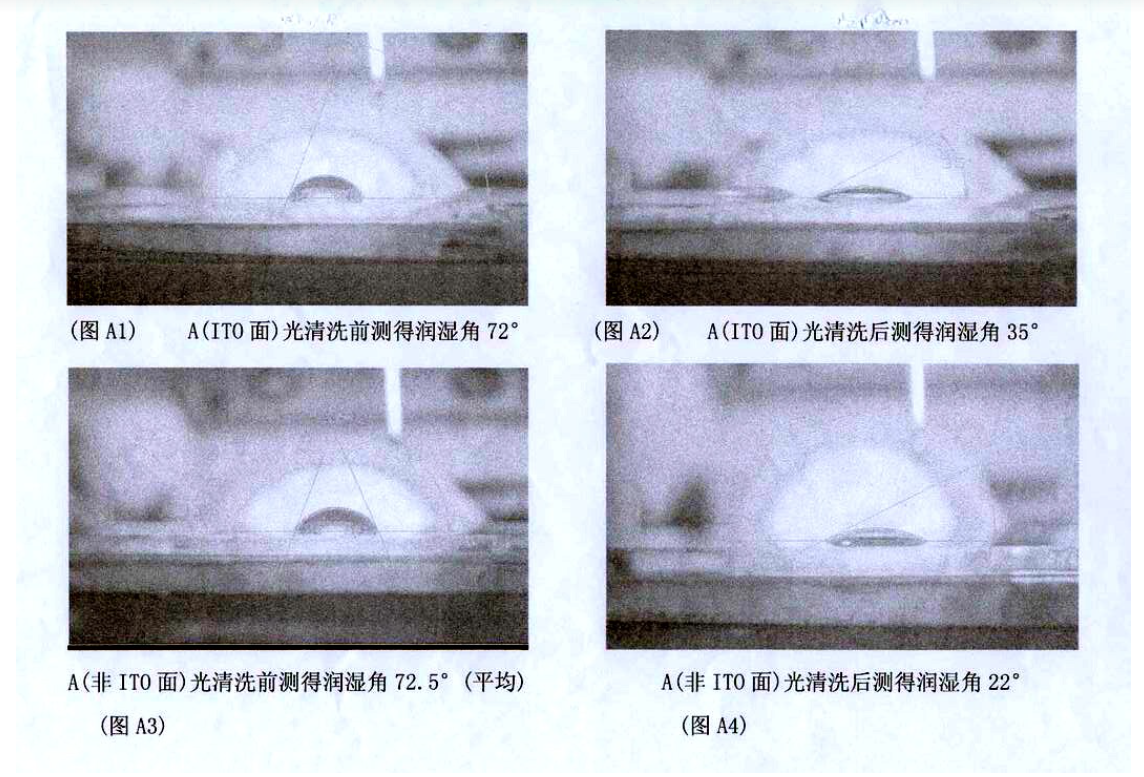

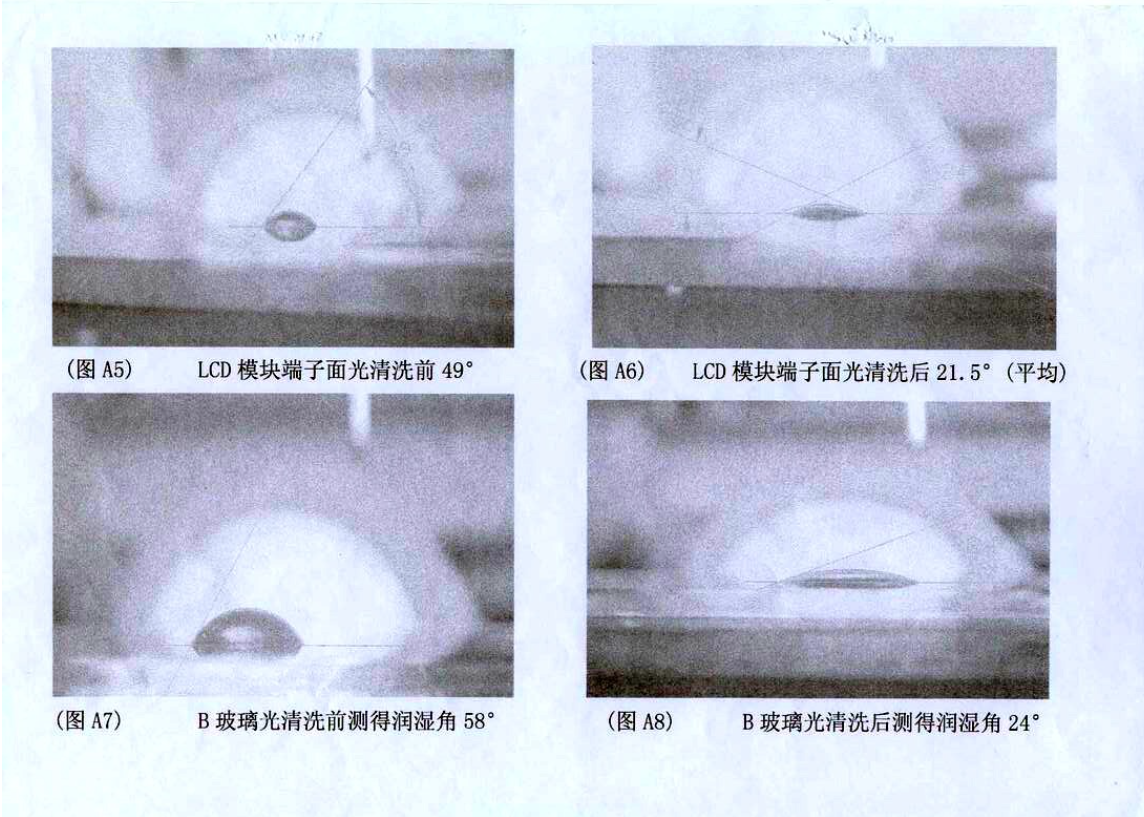

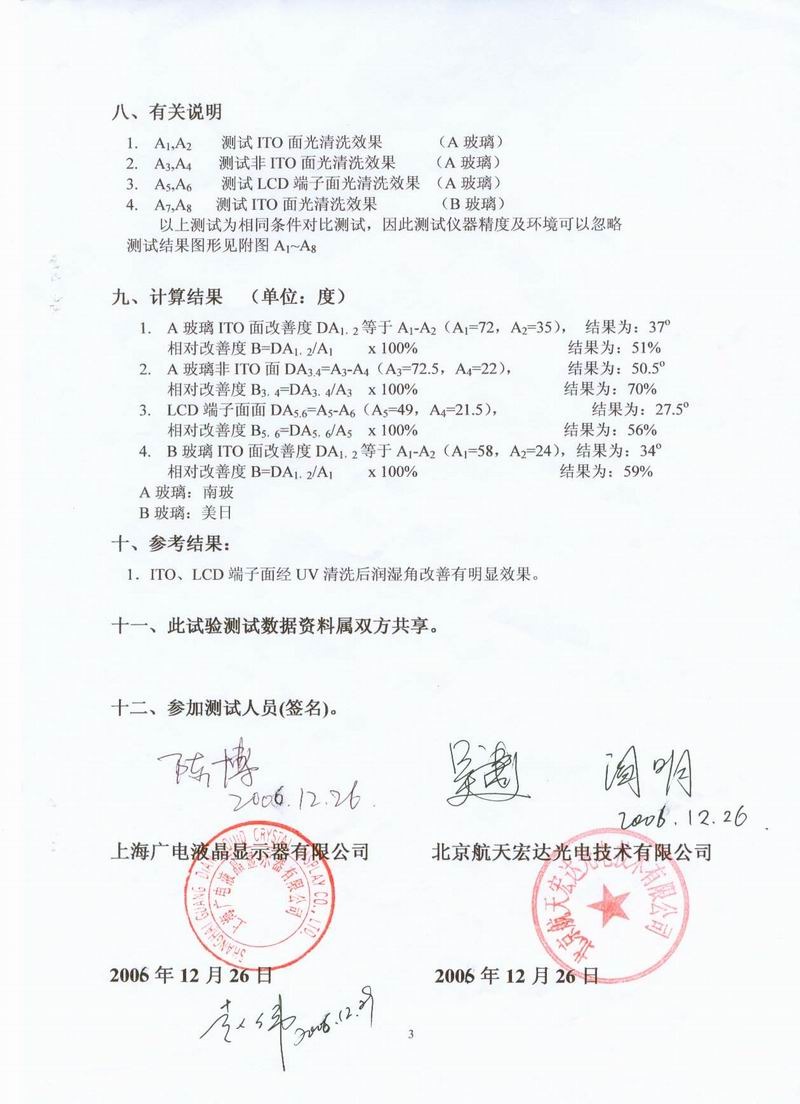

Test Report on UV Light Cleaning Machine of Shanghai Radio and Television LCD Display Co., Ltd

User Report of School of Chemical Science and Engineering, China University of Petroleum (Beijing)

Functional Interface Materials Group, Institute of Chemistry, Chinese Academy of Sciences

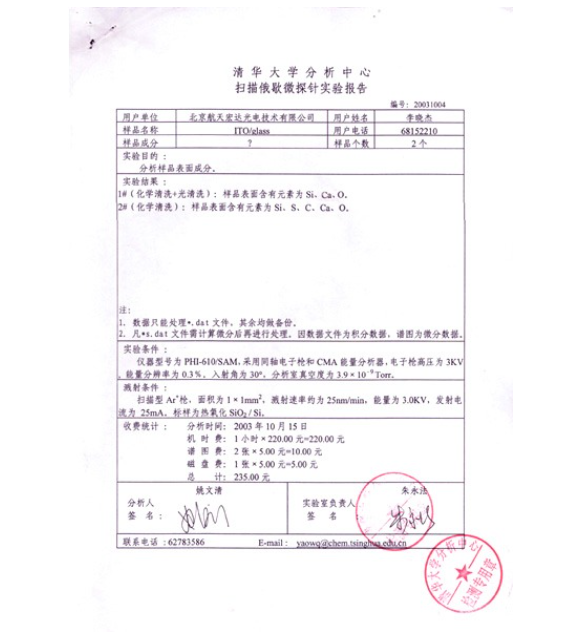

Tsinghua University Auger Report

BIONZONE Pure User Feedback

In addition, most domestic universities and research institutions are our users. In many scientific literature and papers, the Aerospace Hongda brand light source is designated for experimentation,

For example, Tsinghua University, Chinese Academy of Sciences, National Center for Nanoscience and Technology, etc. We have also made spectral lamps for calibration of astronomical telescopes at the National Astronomical Observatory

Aerospace Hongda Special Light Source

In years of scientific research and production activities, we have adhered to a scientific attitude and a pragmatic spirit. For Aerospace Hongda, developing ultraviolet light sources was considered a novice in 2003, starting from scratch.

Professor Cai Zuquan, a renowned expert in electric light sources in China and Vice President of Fudan University in Shanghai (known as the "father of light sources" in China), participated in the research and development of special light sources for Aerospace Hongda and proposed two important points:

1) Light source material

2) Production process

Aerospace Hongda spent a year independently developing a vacuum ultraviolet spectrometer through technological innovation, solving the problem of testing light source materials. At the same time, through repeated practice and exploration, typical processes have been developed to pursue high-quality results in the production process.

The ultraviolet disinfection method was first applied in the United States (in 1970, the US Environmental Protection Agency completed the first demonstration project of ultraviolet disinfection of sewage), and is now widely used in the United States and Canada. After more than 30 years of development, ultraviolet technology has become a mature, reliable, efficient, and environmentally friendly disinfection technology, and has been widely applied in many fields abroad. UV disinfection technology is the latest generation of disinfection technology that emerged in the late 1990s internationally. It has a wide range of applications in the fields of air and water treatment, integrating optics, microbiology, electronics, fluid mechanics, and aerodynamics. It has the characteristics of high efficiency, broad-spectrum, low cost, long life, large water volume, and no secondary pollution, and is internationally recognized as the mainstream disinfection technology of the 21st century Sterilization and disinfection are the main functions of ultraviolet technology in the fields of air and wastewater.

Many industries in our country are in great need of applying ultraviolet technology, such as the food and beverage industry, pharmaceutical industry, cosmetics industry, health products industry, high-end manufacturing industry, high-tech industry, and so on. At present, there is a significant gap between China's application promotion and that of foreign countries. The application of core technologies and components in a few projects relies on imports, and research achievements with independent intellectual property rights cannot develop rapidly due to the lack of sufficient R&D investment and policy support, which also affects the transformation of existing achievements.

Innovation in core ultraviolet technology, development of national industry, and participation in international market competition.

(1) The domestic UV industry is relatively backward. Most of them are in a simple integrated state. The final performance is limited by the level of ultraviolet light source and power supply, making it difficult to make technological breakthroughs. By innovating core technologies, especially core components, the successful development of new, efficient, and high-performance light sources and power supplies will drive the rapid development of this field in China.

(2) Introducing modification processes for new nanomaterials and new quartz materials (key materials for light sources). It can significantly improve the lifespan of existing light sources. Reducing operation and maintenance costs and promoting the popularization of future industrial system products.

At present, the domestic ultraviolet industry operates in isolation at a certain link in the industry chain, which limits the development of technology. Due to the wide range of professions and industries in this field, there is a lack of mutual understanding. It is difficult to develop a single technology field to form an application system with a certain level, and the research and development of key components such as special ultraviolet light sources and power supplies are difficult to meet the requirements of the system. Enterprises engaged in application systems, on the other hand, do not understand the former technology, making it difficult to propose precise requirements and match them; And the light source power supply is another field different from the light source industry. The coordination among the three parties is more complex. Moreover, the existing system of system enterprises makes it difficult to ensure that the achievements of light sources and power supplies are exclusively enjoyed by the system enterprises, and intellectual property rights cannot be effectively protected.

The core content of ultraviolet technology includes light source, power supply, and application system. Being three different industries; There is a very close matching relationship between them

Only with a "three in one" (or N-in one) system where one enterprise completes the entire industrial chain, can the best matching of key links in the industrial chain be achieved, and prominent contradictions in the coordination of each link be overcome, enabling rapid development of ultraviolet technology innovation. And Aerospace Hongda is an enterprise with this advantage. We combine the research and production of light sources, power supplies, and application systems, so our product performance is more stable. Because we have the ability to develop core components, we also have good product innovation capabilities.

(2) Technological innovation

*Light source innovation: Developing new light sources (pulse light source, infinite light source, high-power ultraviolet light source, and special light source suitable for water treatment)

*Power innovation: Develop a matching light source power supply and achieve perfect matching with the light source and system.

(3) System innovation:

1) In system design, the three parts of the industrial chain achieve high-quality matching; And keep synchronized

2) In system design, we pursue excellent sterilization and disinfection effects, and adhere to the combination of UV core technology and other applicable technologies.

3) Utilize existing research and development achievements (various independently developed sensors, dedicated circuits, detection systems, etc.) to achieve the intelligence of the system.

The current situation and trends in China are due to the demand for environmental protection

UV technology will become the mainstream technology and development trend in the fields of water pollution control, sterilization, and disinfection

(1) The current situation of domestic development lags far behind developed countries abroad, with few proprietary intellectual property rights. Basically in the position of agency, technical support, and service for large foreign companies. Even with their own products, they are mostly low-level integrations. Especially for some high-performance core components - light sources and power supplies, they mainly rely on imports.

Although some larger companies in China also have similar products; But it is not its main product (mainly lighting sources; its products and technology still have a long way to go compared to foreign countries, making it difficult to meet the needs of water pollution control.

(2) Developed countries abroad have a history of several decades in the field of ultraviolet applications, gradually forming multinational corporations with upstream, midstream, and downstream industrial chains through continuous mergers and acquisitions, and monopolizing most of the international market. We are currently entering China to seize the domestic high-end market.

(3) The international ultraviolet environmental protection field has gradually entered diversification (targeting different application objects), large-scale, specialized, and automated. The core components of the light source and power supply are developing towards high power, high efficiency, and high performance.

(4) New types of light sources and power supplies have entered the application of system products in developed countries such as Germany, the United Kingdom, and the United States. However, the updated core components of light sources and power products are mainly undertaken by small and medium-sized enterprises and universities, and are currently in the development stage, with a distance from industrialization.

Existing domestic technological foundation

(1) UV application technology is mostly in the stage of imitation, digestion and absorption, but colleges and universities have developed in theory and gradually formed a system. Environmental majors have been established in universities, but UV technology is relatively weak, and cooperation between industry, academia and research is relatively weak in this field.

(2) Although there are technological achievements in UV light sources and power supplies, especially in products specifically designed for water treatment systems, the application research results are very poor, which makes the "achievement transformation" still stuck in theory and unable to achieve the effect indicators and environmental protection standards in engineering practice; Strengthening applied research is imperative.

(3) Although some large listed companies produce light sources, their main business is still focused on lighting sources, with insufficient investment in the research and development of ultraviolet light sources and new light sources for water treatment. Mainly because the market has not yet formed. This is related to the inadequate implementation of national standards, environmental standards, and mandatory measures.

(4) Developing UV systems and light sources. Due to the rapid development of manufacturing industry in China, it has a good industrial foundation and relatively lower costs, raw materials, production equipment and supporting advantages compared to foreign countries, which provides a good foundation for the development of this industry.

(5) Colleges and research institutions in this field have a certain foundation in basic research and development, and the corresponding peripheral fields are relatively complete and complete; But the research direction is not clear enough and lacks integration with the industry chain and enterprises. In the future, it will be driven by the industrial chain. Take the path of combining production, education, and research. It is very beneficial for the technological development of our country in this field.

Existing research and development experience, technological achievements

The company has 17 years of research and development experience in ultraviolet technology since 2003. It started with the introduction of ultraviolet radiation cleaning technology from abroad and went through system integration. It was found that the core components, special ultraviolet light sources, and power supplies could not be solved, and the domestic technical indicators could not be met, resulting in import bans from foreign countries. The blockade abroad has forced us to strive for independent research and development, starting from the core component of the light source and eventually transitioning to the process of system development.

(1) In 03-04, we will focus on breakthroughs in special ultraviolet light sources

(2) Synchronous development of light source power supply (electronic ballast research and development)

(3) Research and development of production testing equipment.

(4) Research and development of light source detection equipment - vacuum ultraviolet spectrometer.

(5) Research and development of ultraviolet radiation cleaning machine

(6) Research and development of plasma air purifier in 05-07

(7) Research and Development of UV Oil Fume Purification System in 08-09

(8) 10 years - Launch of water treatment and research and development of a "ship ballast water system" to address international biological invasion issues.

This includes:

a. Research and development of key components for water treatment systems, development of various measurement and control sensors, and computer control units

b. Cooperate with the research and development of high-power power sources for ballast water.

c. Research and development of high-power medium pressure mercury lamp

d. Research and development of ballast water testing system.

(9) During the project, research and development of non-standard equipment for special light source production experiments will be carried out according to different stages.

Obtained scientific research achievements

(1) Developed a key equipment for special light source detection - vacuum ultraviolet spectrometer. Capable of measuring light waves ranging from 50-300nm. Make it a key detection equipment for special ultraviolet light sources. Domestic peers do not have it (there are only a few imported equipment in China, most of which are used in the aerospace and nuclear industries).

(2) Developed specialized experimental production equipment for special ultraviolet light sources (not available on the market).

(3) Developed a high-power 300W ultraviolet light source for the field of photochemistry. It has been used in large ship equipment, military ultraviolet communication, and new organic thin film photovoltaic materials (used by many universities, research and development institutions such as the Chinese Academy of Sciences) and other fields. Solved the surface treatment problem of modern materials. In addition, it is also used in the semiconductor industry for epitaxial testing of chip modification processes. Replacing the original chemical method greatly improves the economic benefits for users. This technology has been granted an invention patent, and there is a foundation for transplanting this technology into water treatment applications. (The core technologies have their commonalities, it's just that the application objects are different.)

(4) The specialized series of special ultraviolet light sources developed by the company have been successfully used in the field of air treatment. The Finnish Biozone pure brand air purifier company has abandoned its original foreign supplier and chosen our core components for more than 10 years. The core components used for air purifiers have entered the international advanced level.

(5) The ultraviolet technology has been applied to air pollution control and the sterilization and disinfection effects of various products, and some indicators have exceeded those of domestic peers. The disinfection effect of this product has passed the sterilization and disinfection effect tests of multiple national level testing units, including the Chinese Center for Disease Control and Prevention, the Academy of Military Medical Sciences, and the National Environmental Protection Product Testing Institute

(6) Multiple varieties of its core components - light source and power supply - have been certified by Europe.

(7) The company's system products and core components have been granted ten authorized patents and intellectual property rights.

(8) The company's UV system products and key components have won multiple national awards

(9) Two products have obtained the Beijing Municipal Independent Innovation Product Certificate and have been included in the government procurement catalog.

(10) In 2007, the "UV Technology Research Institute" was established (registered with the industry and commerce bureau and recognized as a "Beijing scientific research institution" by the Beijing Municipal Science and Technology Commission)

(11) In 2011, an industry university research agreement was signed with a domestic home appliance light source university, which became their internship base. Excellent graduates were selected to join the enterprise, and professional technical backbones in the field of electric light sources who had worked for many years in foreign enterprises (well-known foreign peer enterprises) were hired as the head of the experimental base.

(12) We have cultivated a group of cross disciplinary and multidisciplinary backbone teams that combine old, middle-aged, and young people to shoulder important responsibilities in the UV industry chain. Especially the R&D personnel in the three parts of the industry chain and the technician team with certain experience and hands-on ability.

(13) We have established close cooperative relationships with universities, research institutions, well-known experts and scholars in related fields. To support the basic research of the school, we have provided free light source test samples for many years; We have established good relationships with research institutions in related fields that complement each other's strengths and possess certain resources.

For example, Liu Wenjun, a professor at the School of Environment, Tsinghua University and an expert in water treatment, is a member of the International Ultraviolet Association

Professor and Doctoral Supervisor at the School of Environment, Tsinghua University - Zhang Pengyi

Professor Cai Zuquan, Vice President of Fudan University and Director of the Institute of Electric Light Sources, is an expert in electric light sources at Fudan University (the father of electric light sources)

Professor Zhu Shaolong, an expert in electric light sources at Fudan University

Professor Zhang Zhonglian and Dr. Tang Yi from Beijing Institute of Technology

Dr. Yuan Guimei and others from China University of Petroleum.

Aerospace Hongda Special Light Source: Aerospace Hongda's "UV Path"

Aerospace Hongda Company initiated the "UV cleaning machine" project in 2001, which required the use of imported UV core components. However, during the procurement process, it was rejected by Japanese companies as the domestic UV light source technology specifications were far from meeting the project system requirements. Faced with foreign "technology blockade" and technological discrimination against China, it has inspired Aerospace Hongda to make its own determination to produce high-quality special ultraviolet core components in China. The company independently developed UV core components and complete system from scratch without any foundation. Without equipment or instruments, I conducted independent research and development. Without funds, I sold my own house and sacrificed everything for research and development.

In 2005, Zhang Runsong, the technical leader of the general manager, led the design and development of the first special ultraviolet light source experimental production line. In 2006, the first key equipment for ultraviolet light source research and development, the vacuum ultraviolet spectrometer, was independently developed. We have developed a unique production process and produced special ultraviolet light sources and power supplies that meet the requirements of the project system.

In 2006, as the inventor, the invention patent for the "UV radiation cleaning machine" was granted. In 2007, the "UV Technology Research Institute" was established, breaking the passive situation of UV core components being "blocked" by foreign countries. Due to its advanced technical indicators of light source and power supply and reliable performance, HTC has become a supplier of core components of the world famous brand "BIZONE" air purifier. After nearly 10 years of dedicated research on ultraviolet technology, our company's ultraviolet core components have gained a certain reputation both domestically and internationally.

In China, there is close cooperation with renowned international point light source expert Professor Cai Zuquan, Vice President of Fudan University, electric light source expert Zhu Shaolong (Professor at Fudan University in Shanghai), Professor Liu Wenjun from Tsinghua University (internationally renowned water treatment expert), and Professor of Optics from the University of Science and Technology, as well as spectrometer expert Li Futian from Changchun Institute of Optics and Fine Mechanics, Chinese Academy of Sciences. "Aerospace Hongda" and Zhang Runsong have had a certain influence in the industry.

In 2008, the UV core component light source and dedicated power supply were successfully developed, with technical indicators leading domestically and catching up with international advanced levels.

In 2009, the "Special UV Light Source Special Production Line" was successfully developed,

In 2010, the "UV Radiation Oil Fume Purification System" was successfully developed.

In 2011, the core technology design scheme for the "ship ballast water treatment system" was completed, and key equipment and core components achieved phased results.